We are in the midst of final preparations before shipping our Hyperloop pod prototype and test dummy to SpaceX’s test-track facility in California. Our team at the University of Edinburgh is one of just 24 from across the world that has got its designs to this stage, with models heading down the half-scale track later this month.

If you’ve not already heard of the competition or its aims - creating an environmentally conscious way to travel between cities like London and Edinburgh in just 35 minutes - check out our last blog on The Engineer.

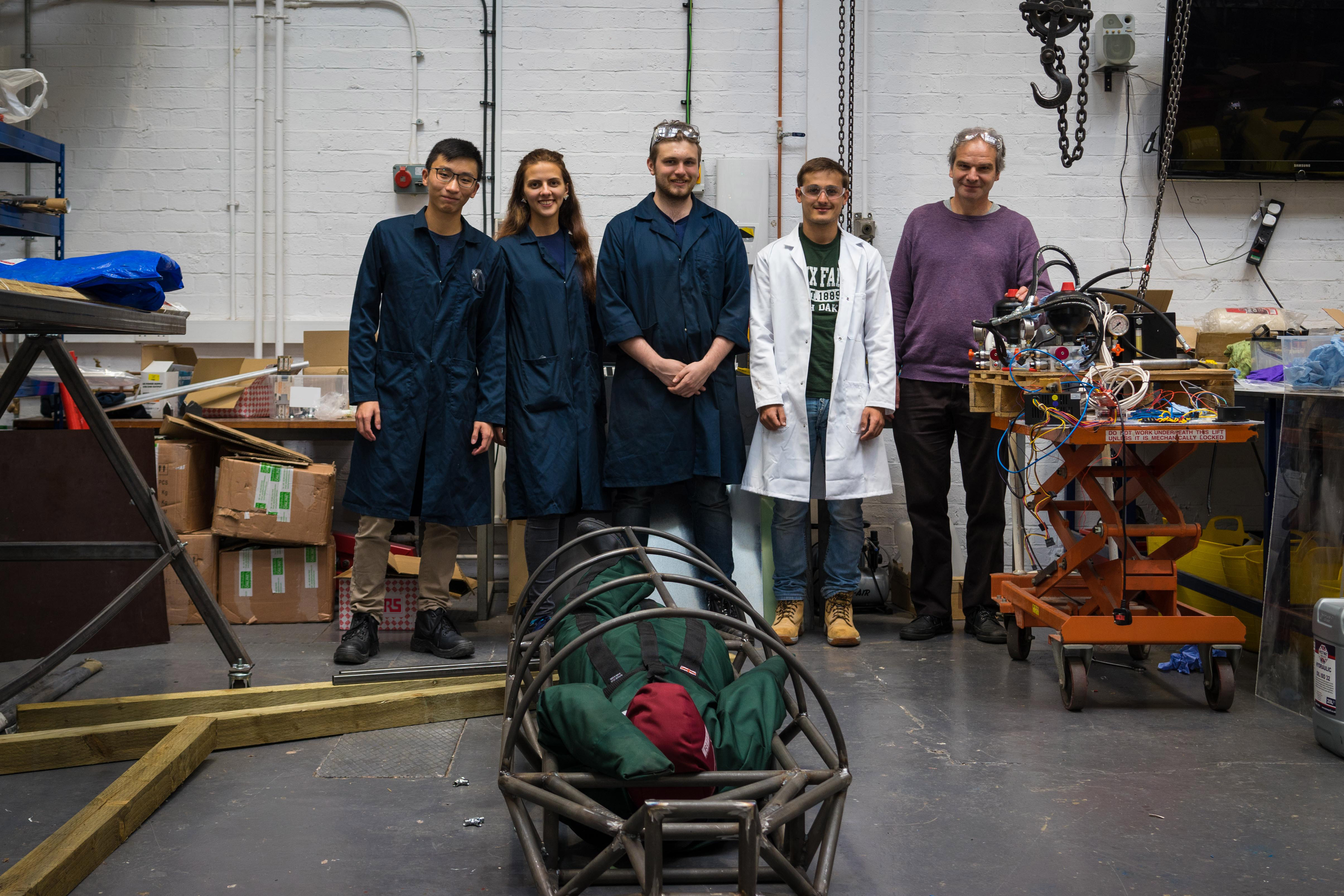

A lot has been achieved by the HypED team, and in this second blog I’d like to introduce our concept pod - Poddy McPodface - and look at some of the biggest challenges we’ve faced so far.

New innovations we’re working on

What we’re trying to achieve is high-speed travel in confined, vacuum spaces. This unique project therefore needs completely new ways of working, and you can’t simply adapt. Indeed, several of our team are currently dedicating Masters theses to the engineering analysis of Hyperloop, looking at things like structural designs for the pod and the Hyperloop tube, the dynamic behaviour of composite materials, levitation methods, and fire propagation in a vacuum.

Can it be done safely and cleanly?

What happens if there’s a leak? How do you cool the system in a vacuum? How big will turns need to be? Part of our work has been looking at the technical and economic feasibility of getting a pod moving at virtually Mach 1 through a tunnel under the UK or, in the case of some proposed Hyperloop projects, between countries and under seas.

Even the smallest leak would be disastrous, with intrusion of air in such a confined space leading to shock waves and damage for the tube, the pod and, not least, the passengers. Next up, components need to be kept relatively cool, but air-cooling them is not an option. Then we need to look at safety systems: can modern electronics communicate quickly enough and activate in time should a power loss event occur? And a particular conundrum: turning while travelling at almost the speed of sound creates significant G-forces. Can routes be created that allow for turning radiuses of 20 km plus? The implications of not doing so would be undesirable, to say the least.

Countdown to the competition

Manufacturing and assembly at the HypED workshop has been non-stop for the past few months. All critical systems and components have been tested for functionality and compatibility, and communication with the base station is working well.

Given the tight time constraints we are in good shape, and on August 10th Poddy McPodface and its first passenger will be on the way California. Look out for our next update on how the testing goes.

Additional details on some of our biggest challenges and how we’re tackling them can be found here.

Poll: Should the UK’s railways be renationalised?

Rail passenger numbers declined from 1.27 million in 1946 to 735,000 in 1994 a fall of 42% over 49 years. In 2019 the last pre-Covid year the number...