Device detects hidden damage in composite aircraft materials

In recent years, many manufacturers have started building their aircraft from advanced composite materials, which consist of high-strength fibres, such as carbon or glass, embedded in a plastic or metal matrix.

Such materials are stronger and more lightweight than aluminium, but they are also more difficult to inspect for damage, because their surfaces usually do not reveal underlying problems.

‘With aluminium, if you hit it, there’s a dent there. With a composite, oftentimes if you hit it, there’s no surface damage, even though there may be internal damage,’ said Brian Wardle, associate professor of aeronautics and astronautics at MIT.

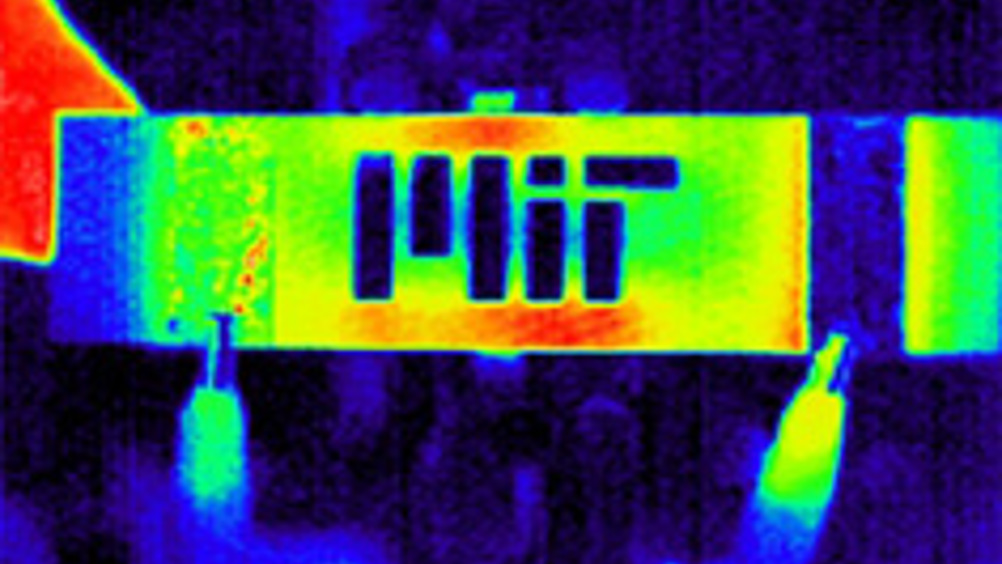

Wardle and his colleagues have devised a new way to detect that internal damage, using a simple handheld device and heat-sensitive camera. Their approach also requires engineering the composite materials to include carbon nanotubes, which generate the heat necessary for the test.

One method that inspectors now use to reveal damage in advanced composite materials is infrared thermography, which detects infrared radiation emitted when the surface is heated. In an advanced composite material, any cracks or delamination (separation of the layers that form the composite material) will redirect the flow of heat. That abnormal flow pattern can be seen with a heat-sensitive (thermographic) camera.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...