According to its developers, the technology could have a range of applications, such as providing enhanced driver awareness by wrapping around the exterior of a car. The sheet camera could also be placed around a lamppost in a public area, providing video images from all directions.

"Cameras today capture the world from essentially a single point in space," said Shree K. Nayar, Professor of Computer Science at Columbia Engineering and the research lead.

"While the camera industry has made remarkable progress in shrinking the camera to a tiny device with ever increasing imaging quality, we are exploring a radically different approach to imaging. We believe there are numerous applications for cameras that are large in format but very thin and highly flexible."

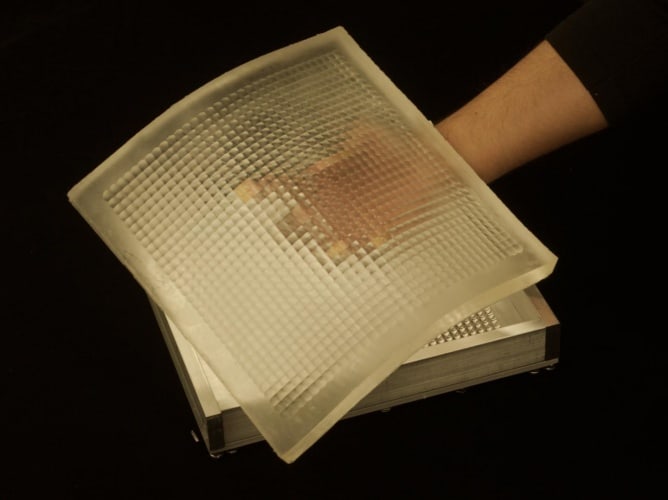

The technology relies on a flexible lens array that adapts its optical properties when the sheet camera is bent. Bending an array of rigid lenses would lead to gaps in the images captured, resulting in what are known as aliased images. By using an elastic material for the array, the focal length of each lens can vary as the sheet is bent, preventing aliasing from occurring.

A prototype lens with an optimised geometry was fabricated using silicone, and the team was able to demonstrate its ability to capture images across a range of deformations.

Nayar and his colleagues envision a future where users have credit card-sized “flex-cams”, with the field of view manipulated simply by bending the device. However, this will require combining the flexible lens array with a thin optical system to project the image.

"The adaptive lens array we have developed is an important step towards making the concept of flexible sheet cameras viable," said Nayar. "The next step will be to develop large-format detector arrays to go with the deformable lens array. The amalgamation of the two technologies will lay the foundation for a new class of cameras that expand the range of applications that benefit from imaging."

Project REvAR aims for energy and clean water from sewage

I struggled to find much detail about <i>this</i> project but it seems to have similarities to another report from 2022...