In 2009, around a billion camera modules shipped worldwide in mobile phones, notebook computers and other consumer electronics devices. By 2012, analysts expect these module shipments to exceed two billion units.

Many of the modern camera modules found in such devices sport some form of auto-focus mechanism, where the lens of the camera is moved back and forth mechanically until the sharpest possible image of the subject is projected onto a CMOS imaging device that is then used to capture an image.

Commonly, such systems work by taking an input from a sensor, processing that signal with an embedded processor and using the result to control a mechanical voice coil actuator that automatically focuses the lens onto an object of interest.

Now, in an attempt to replace the electromechanical systems found in such devices with a solid-state alternative, California-based LensVector has built a tuneable liquid-crystal lens that it believes could become the de-facto standard for mobile devices over the next few years.

The development of the device is the result of research work undertaken at the laboratories of Prof Tigran Galstian, who developed the liquid-crystal lens technology at Laval University in the Centre for Optics, Photonics and Lasers in Quebec, Canada.

In 2006, having secured a worldwide licensing deal for the technology from the university and with backing from 30-year-old venture capital firm Menlo Ventures, LensVector was formed by its present chief executive officer, Derek Proudian, to commercialise the technology that Galstian developed.

To that end, the LensVector team has spent the last four years in ’stealth mode’, refining the technology and developing a commercially viable product based upon it. Only earlier this year, just prior to the Mobile World Congress in Barcelona, did the company announce it was in full-scale commercial production of the devices.

The technology takes advantage of two common properties of liquid-crystal molecules - properties that have already been widely exploited in the development of liquid-crystal displays over the past 40 years.

The first is that, as liquid crystals are essentially dipoles, they can be rotated in response to an electric field. The second is that, owing to their anisotropic nature, the liquid-crystal displays are b-refringent; the amount that the light is refracted by the liquid-crystal molecules depends upon whether it passes through their ordinary or extraordinary axes.

’The breakthrough made by Galstian, however, was that he developed a new method to precisely control the rotation of the liquid-crystal molecules across a liquid-crystal cell, essentially creating a solid-state lens capable of producing a good-quality image,’ said Proudian.

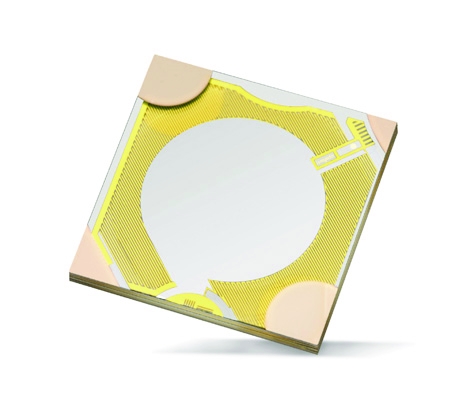

LensVector’s solid-state lens resembles a Peruvian triple sandwich. On one side of the device is a filling of liquid-crystal material that provides the optical function of the device, while on the other side there is what the company calls a hidden layer.

Both the liquid-crystal and hidden layers are held in place by three glass substrates, and the inner sides of the very outer glass substrates have been sputter coated with thin conductive planar electrodes using a standard thin-film deposition process to provide a means of supplying a control voltage to the device.

’The hidden layer is the secret sauce that enables the liquid-crystal material to act as a lens,’ said Proudian. ’It is composed of two completely transparent materials that have exactly the same refractive index but with very different dielectric properties.’

As there is no difference between the refractive index of the two materials in the hidden layer, light passes through the hidden layer without being refracted or distorted. But as the dielectric properties of the two materials in the hidden layer differ, when a voltage is applied across the two planar electrodes the strength of the electric field applied to the liquid-crystal material is modulated by it.

The hidden layer shapes the electric field that the liquid-crystal molecules experience, controlling the amount that the molecules rotate and hence the amount by which they refract the light passing though them, thereby allowing them to focus the light passing through the cell.

’Because the hidden layer generates a dynamically tuneable shaped electric field, the molecules in the device can be rotated to adjust its focus to any desired focal distance - from 10cm to infinity,’ said Proudian. He added that one of the main properties of the solid-state lens is that it maintains a very good spherical profile as it moves from infinity to near focus. Although the company specifies the near-focus distance of the liquid-crystal lens at 10cm, Proudian claims that the company can develop lenses that can focus closer than that if required.

’The fact that there is really almost no optical distortion as the device changes state as the control signal is applied makes the device not only suitable for auto-focus cameras but also makes it good for micro-video applications where it provides a smooth response and distortion-free image as the camera moves from far field to near field,’ he said.

Proudian added that the speed of the new solid-state lens is comparable to a voice coil motor, or other kind of mechanical actuator, that is presently used in mobile phones.

’We worked very hard when developing the device to find the right trade-offs between the voltage that we need to drive the part, the rotational speed that we can get out of the molecules and the choice of liquid-crystal molecules that we use to achieve good optical quality, speed and performance,’ he said.

While the new auto-focus device has been qualified to meet the environmental and reliability requirements specified by mobile phone makers, the company claims that since camera lens modules based on it will have no motor or moving parts, they will offer far better shock and vibration characteristics than mechanical solutions. While mechanical offerings are rated at a few hundred thousand operations, the LensVector device has been rated at 10 million operations.

To create the devices, the company has leveraged existing production techniques from the liquid-crystal and semiconductor packaging industries that are used in mobile phone and consumer electronics manufacturing.

’We deliver our devices to our customers on standard wafer-dicing tape, which is exactly the same way that CMOS sensors and other semiconductor parts are delivered, so the handling and processing of the devices by camera module integrators is almost identical to the way in which they already pick and place semiconductor parts onto printed circuit boards, enabling the manufacturer to save costs assembling the devices into modules,’ said Proudian.

He added that the company’s vision is to replace all mechanical aspects of cameras and other mobile devices with solid-state alternatives. LensVector is currently negotiating deals with several high-volume manufacturers of camera module integrators and other suppliers in the mobile handset and consumer electronics supply chain. At the moment, however, Proudian is reluctant to disclose details of the companies for confidentiality reasons.

design essentials

The key facts to take away from this article

- LensVector has refined Prof Galstian’s liquid-crystal lens technology

- The solid-state lens is capable of producing a good-quality image

- They offer better shock and vibration properties than mechanical systems

- The devices are supplied to customers on standard wafer-dicing tape

AI-generated medical responses need monitoring, study finds

This would negate most of the benefit of using AI in the first place, rather like the Locomotive Act 1865 that required any self-propelled road...