The ‘Productivity Puzzle’ is set to become one of the biggest business debates of 2015, with the Chancellor expected to base a large part of his budget on helping the UK move up the international league tables.

Before I go any further, let me try to define what productivity actually means. There are numerous definitions being put forward, but perhaps the easiest one for us to relate to is;

‘A measure of the efficiency of a person, machine, factory or system in converting inputs into useful outputs.’

The ‘Productivity Puzzle’ comes from the unexplained disparity between UK economic performance improving and labour productivity per hour worked actually falling.

Solving this appears to be the topic of choice for the media, politicians and economic commentators and it’s not difficult to see why.

We have seen more than 1million new jobs created in the last two years and there is real evidence of growth in the economy, yet productivity does not match the levels we were seeing pre-2008.

Whilst we all welcome the economic improvement seen in recent years, labour productivity per hour worked has fallen by over 15% from the national level achieved before the financial crisis. If not corrected this has the potential to be very damaging for the economy and living standards in general.

Experts have been struggling to explain the reasons for this collapse, pointing to low pay and misdirected investment in sluggish companies as possible culprits.

Others have suggested that a failure to upskill existing staff has restricted many of our companies from performing to their full potential, whilst the CBI suggest that a simpler tax regime could play its part in securing greater productivity.

The manufacturing sector is performing rather better, recording higher-than average productivity when compared with the service and financial sectors.

Our recent Manufacturing Barometer survey, which questioned the leaders of over 500 businesses, provides strong clues as to why manufacturers are bucking the trend and, importantly, how they are doing it.

The overriding feeling from the report is one of optimism, with 70% expecting sales turnover to increase in the next six months.

They believe that economic growth will be achieved alongside increased employment, with 55% predicting a rise in staff numbers. The difference between these figures could suggest better productivity will be a given, but that would be ignoring the 84% of manufacturers who recognise the need to improve productivity even further.

That sets up the intriguing question; how could they grow and at the same time be more efficient? The answer can be partly found in targeted investment.

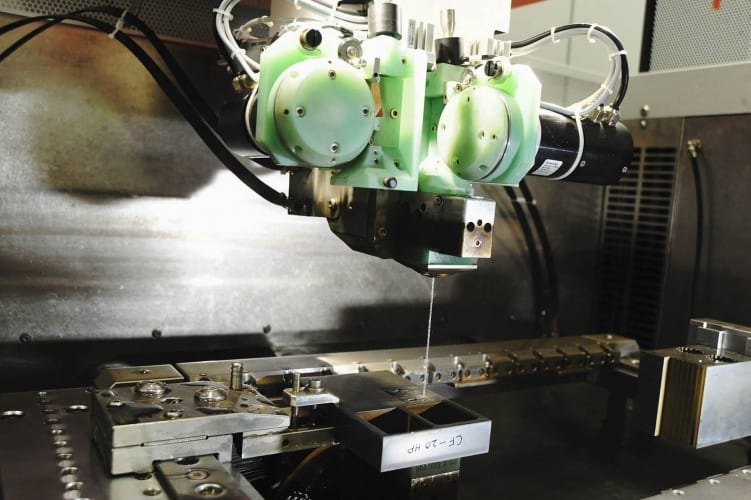

Over half (53%) of our SMEs expect to increase their investment in machinery and premises and 95% will not let the level of investment fall. This commitment to investment is fuelling innovation in new product development and more efficient processes.

Over the last thee years, the Business Growth Service has committed £18m of tailored manufacturing support through the Manufacturing Advisory Service (MAS) to assist businesses in making vital improvements with view to increasing Gross Value Added (GVA) and creating jobs.

Our Business Growth Managers – who work with ambitious firms to help them overcome barriers to growth – were able to support management teams to introduce lean manufacturing, improve scheduling, put in better supply chain management controls and secure finance towards the purchase of new machinery.

One such example is precision presswork and stamping specialist Brandauer, who tapped into external assistance to boost its sales and marketing activity and improve its raw material utilisation by 45%.

The latter played a crucial role in the Birmingham-based company securing a £2m reshoring deal that will see it supply components all over the world, including China, India, Mexico, UAE and the United States.

It is now setting its sights on even more international ‘wins’, with a special focus on securing greater market share in Germany that could eventually lead to a £10m turnover by 2017.

Balancing Act

However, investment in technology and process is only one part of the productivity equation. Equal priority needs to be given to developing your people and in ensuring they have the necessary skills to implement improvements and support growth.

This isn’t just a quick fix; it’s about taking a more holistic look at your company, building a high performance team, embedding a culture of innovation and identifying skills for the future.

Again, through the Business Growth Service, we have committed £35m of funding in this area so that firms will be better able to make the right decisions and complete the business improvements they need. We are also able to actively direct SMEs towards apprenticeship schemes and other training.

This positive outlook from our manufacturers and their commitment to invest all bodes well for improved productivity. These same strategies could be just as effective in solving the issue in other sectors, targeting improvements in people, processes and technology.

Get the balance right and we may just have found the elusive answer to the ‘Productivity Puzzle’.

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...