A new system based on pumped hydro generation promises to vastly increase capacity to store and release energy generated from renewables, providing a more environmentally-friendly alternative to batteries.

The breakthrough in the system being developed by start-up RheEnergise is a bespoke fluid with a density 2.5 times that of water. The company says this opens up a huge number of potentially suitable sites.

Electricity supply has always faced the problem of dealing with a mismatch between supply and demand. In the past huge coal-fired power stations were designed to run for long periods at a constant output and could not easily respond to peaks and troughs in demand. One method devised to address this was pumped hydro storage, in which water is pumped into a dam at off-peak times, and then released to generate hydro-electricity and balance the grid when needed. But because of the need for high heads of water to generate the necessary power it was limited to mountainous sites in Scotland and Wales.

The need to store energy is becoming more acute with the growth of renewables, especially wind power, because of their intermittent nature, and the problem will be compounded by growth in the numbers of electric vehicles and heat pumps for domestic heating. BloombergNEF predicts a hundredfold growth in global energy storage between 2018 and 2040.

Methods of storing energy for recovery later include batteries, capacitors, compressed air and many others. RheEnergise believes its High-Density Hydro system will be cheaper, relatively straightforward to construct, and with low environmental impact.

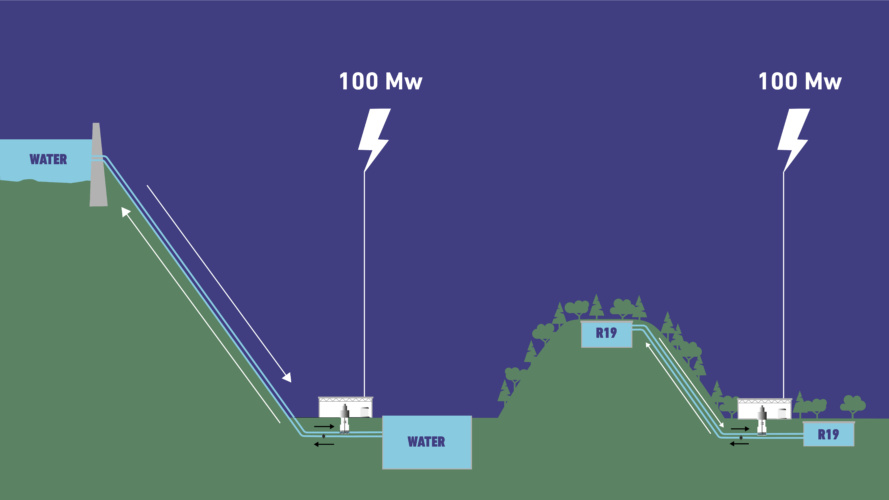

The advantage of the new high-density fluid, known as R-19, is that the vertical elevation needed to generate a given level of power is reduced by a factor of 2.5. So is the volume of storage, reducing construction costs. Pipe sizes can also be reduced. The system could be installed with a typical head of 2-300m or less, making hundreds of moderately-sized hillside sites potentially suitable.

HD Hydro would operate as a closed system, with storage tanks at the top and bottom, which could be buried underground or in the hillside. The tanks would be connected by underground supply pipes or penstocks, feeding reversible pump/turbines to generate power. A typical plant would provide 10MW to 50MW power and have two to 10 hours of storage capacity. It would occupy about 1ha, it is estimated.

Prof Richard Cochrane, associate professor for renewable energy at Exeter University, is also chief innovation officer at RheEnergise. He says that the project was sparked off by the university researching a number of storage options. Pumped storage had the advantage of low embodied energy and didn’t require scarce minerals, but was limited by the availability of sites. Stephen Crosher, founder of RheEnergise, raised the question of whether there were high density fluids that could be used. The two had worked together when Cochrane led the development of the Quiet Revolution QR5 vertical axis wind turbine.

With a grant from Innovate UK the university’s Renewable Energy Group, assisted by Camborne School of Mines, began exploring the feasibility of a number of possible fluids. The R-19 fluid was developed and its performance proved in nine months. Producing a fluid significantly denser than water at room temperature is a considerable challenge – the maximum density of a solution of common salt, for example, is around 1200kg/m3. The company has revealed only limited details of R-19, saying only that it is a finely divided mineral suspended in water, easy to manufacture and safe for the environment.

Cochrane said: “The density of the fluid could be increased further, but this has consequences for viscosity.” With the current fluid the team has found a “sweet spot” where high density is combined with viscosity only fractionally greater than water.

The fluid appears to cause only low levels of abrasion to the pump/turbines, though this is being studied further. Settlement of the mineral is also not expected to be a problem. “We’re confident it will stay in suspension for a good period of time, greater than the length of our cycles,” Cochrane said. He added that another advantage of the dense fluid was that “we can get the same power out of a smaller turbine”.

The company predicts an efficiency of 83% for the storage and regeneration cycle, and there are no parasitic loads, such as the need to cool batteries. “We’re confident of getting at least 83%, and working to try to improve on that,” said Cochrane.

The reversible pump/turbines are another area of innovation. “We’ve done computational fluid dynamics and physical testing to optimise the geometry of the turbine for the heavier fluid,” Cochrane said. “We’re pleased with the performance but we think there’s still some improvement to be gained from further iterations.” TÜV SÜD NEL in East Kilbride supported the CFD analysis.

An unexpected partner in the project is Eminox, best known as supplier of emission control systems to the automotive industry, which announced in February that it is developing the control system for the project. This will manage the flow of the fluid between tanks, the pump turbine and generator operations, and will interface with the local electricity grid to manage power supply. “Eminox are using their experience in integrating sensors, monitoring pumps, mixtures and so on. They were keen to apply these skills to a new area,” said Cochrane.

Separately, work is under way to develop a way of monitoring the fluid to make sure there is no settlement, not a straightforward task, Cochrane says.

Regarding construction of an HD Hydro project and the need to gain the necessary consents, the main environmental impact would occur during the construction phase. Cochrane said that if the storage tanks were buried, visual impact would be reduced, but there would be significant excavation and disposal of spoil, with the possibility of finding archaeological remains. After that the impact would be very low, he said.

RheEnergise believes that HD Hydro will be highly cost-effective. It expects the levellised cost of energy, the standard method for comparing the cost per MWh of electricity from different sources over the lifetime of the plant, to be 40% below that of a lithium-ion battery project. Whereas batteries have significant end-of-life disposal costs as well as the need to extract lithium at the outset, HD Hydro projects will have few end-of-life liabilities and zero emissions in operation, the company says.

Cochrane added that there is likely to be space in the market for several different storage modes operating on a range of timeframes. There would be a role for batteries for short-term storage where there is a need for high power but low total energy, for example in grid management. Batteries would be less suitable for longer-term storage or larger amounts of energy. “We think we can do both – we can certainly do fast response, but also have capacity for longer-term storage as well,” Cochrane said.

Applications for HD Hydro could include therefore include grid balancing but it could also help a wind farm to maximise income, by storing energy when the pool price of electricity was low but the wind was strong, generating electricity later to sell when the price rises.

A mapping study using GIS analysis has identified 9,500 potentially suitable sites in the UK alone, with around 700 estimated to have a 70% chance of development success. The sites of most interest are mostly rural, with good grid connections. Among possible sites discovered is a wind farm in an old quarry, where the existing landscape is well suited to the requirements of an HD Hydro installation.

The company has raised £823,000 on crowdfunding site Crowdcube to take development to the next stage. It is exploring a number of possible locations for a large-scale demonstration of a fully operating system. “We very much want to move that forward, to have an operating system that is really demonstrating the final project. It won’t be perhaps the scale that we want to get to ultimately, but it will still be a substantial scale project,” said Cochrane.

The sites being considered offer scope to demonstrate different balances between power versus total energy; meanwhile work continues on pump and turbine optimisation and improving full-cycle efficiency. The company is also keen to look into prefabricating the system, for example with penstocks and turbines supplied as a single unit.

HD Hydro schemes would be relatively quick to build and it is expected the demonstrator could be operational quite soon. “We very much hope to get something operating in 12-18 months,” said Cochrane. The initial demonstrator may have an output of 500kW but the company hopes to be able to produce a 5MW system soon afterwards. “We’re hoping to be able to do that within a few years, maybe three years or so,” Cochrane said.

Labour pledge to tackle four key barriers in UK energy transition

I'm all for clarity and would welcome anyone who can enlighten me about what Labour's plans are for the size and scale of this Great British Energy....