Growing up I was always interested in novel technical challenges. Perhaps unsurprisingly, I jumped at every chance to attend engineering summer schools and school trips. One of those was the Schools Aerospace Challenge where a team from my school was shortlisted for our design of a long endurance airship, giving us the opportunity to fly a plane and a helicopter. This is also how I first met Per Lindstrand, the inventor and explorer, who ran a company that specialised in creating brand new solutions for specific applications - exactly what I’d always been interested in.

Later on, when completing my undergraduate degree at Warwick, I remembered Per Lindstrand and Lindstrand Technologies. I needed to work during my holidays to earn money, and so decided to apply for work experience there. Per gave me responsibility for my own project designing and building a machine for testing the rate of helium permeation through fabrics. It fitted me perfectly – no such machine was commercially available, it was entirely novel. After one successful summer, I returned for Christmas and the following year.

Clearly used to having me around, my boss there one day left the details of the engineering doctorate programme at University College London next to me saying only: ‘This sounds interesting…’ Needless to say it was enough to pique my interest. Per Lindstrand had actually conceived the programme, which was to design a fabric thermal chimney. I applied and was accepted, in large part because I had already had experience working in the field and with the company.

Designing a fabric solar thermal chimney

Per Lindstrand knew a physicist who worked on the new Atacama Large Millimeter/submillimeter Array (ALMA) at the European Southern Observatory (ESO), in the Atacama Desert, Chile. The system, under construction at the time, was to consume a huge amount of power. The ESO is currently powered by diesel generators but transport of diesel fuel and reduced efficiency at high altitude contribute to enormously high CO2 emissions and energy costs.

Solar thermal chimney power plants offered the potential to reduce cost and environmental damage. To operate a solar thermal chimney you first cover large areas with transparent material (plastic film or glass) to create a solar collector which heats up the air underneath via the greenhouse effect. The air becomes buoyant as its temperature increases and its density decreases. Hot air rises under buoyancy (think of a hot air balloon – Lindstrand Technologies’ original products).

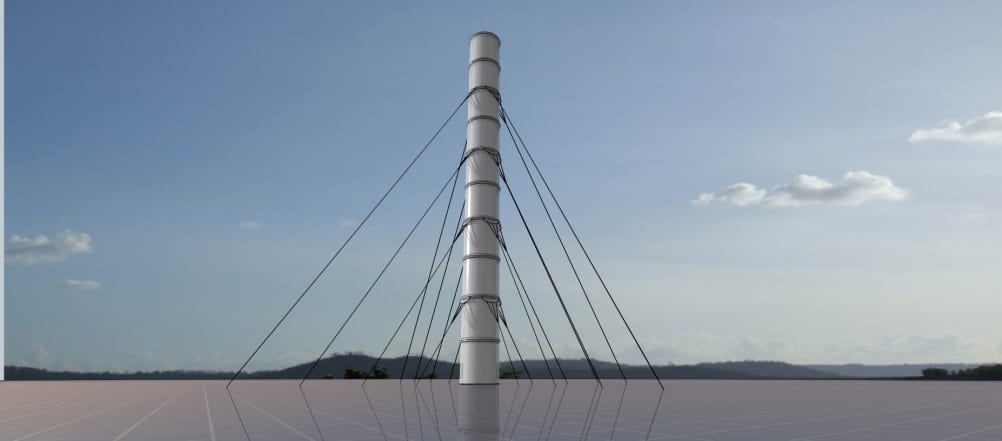

A tall chimney is placed at the centre of the collector and the buoyant air flows through the collector and up the chimney. A set of air turbines is located at the base of the chimney to extract power from the airflow. If you can build one on a large scale, with the chimney 500-1000m tall, you can get around 150 MW out of it - which is enough to power more than 50,000 homes in the UK.

Furthermore, the power source needn’t be the sun; the thermal chimney concept could be used to extract power from low-temperature industrial waste heat or any other low-temperature heat source.

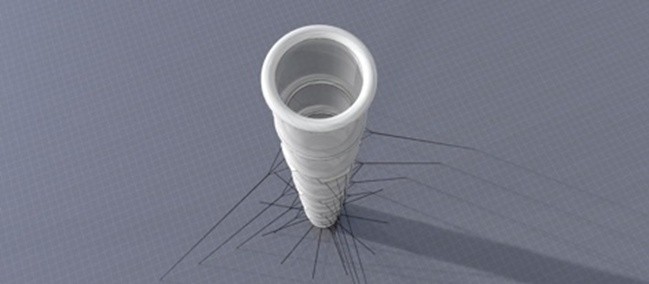

However, tall chimneys are very difficult and expensive to build. This is where Per Lindstrand had the idea of a fabric chimney. Because it would be very light, transport requirements would be minimal and it could also be deployed in months rather than years. However, manufacturing a chimney from fabric and holding it aloft with envelopes of lighter-than-air gas is quite a challenge and technologically beyond the remit of one student working on a four year programme. My project is therefore a feasibility study taking the first step towards that goal.

I started with in-depth studies of thermodynamics and then moved on to applying this to a solar thermal chimney. Currently, I’m starting to look more at inflatable chimneys and have built a small-scale prototype to get data on stiffness and to provide a benchmark for future designs.

Engineering doctorate: study, work and get paid

The engineering doctorate (EngD) programme is designed with company involvement in mind. It keeps me in touch with the commercial world and with industry, whilst Lindstrand gets access to research as it progresses and has a say in where it goes.

I was happy to be able to take advantage of another important opportunity in the form of the Industrial Fellowship programme run by the Royal Commission for the Exhibition of 1851. A friend prompted me to apply after learning that the Commission provides funding for projects investigating novel technological ideas with the potential to contribute to British industry.

The Fellowship provides a total of £80,000 of funding over three years to students from any British university pursuing a PhD or EngD with industrial involvement. This financial backing has enabled me to do more than I would have been otherwise able to. In fact, I wouldn’t have been able to build the first prototype without it!

Beyond financial backing, my Industrial Fellowship has also connected me with new, invaluable contacts, and access to lots of useful events. One event at the Royal Society, about agricultural technology, opened up a whole new world of potential applications for the chimney that I hadn’t even thought about: using the equipment to aid solar drying (of wheat, tomatoes, minerals).

If I were to do it all again…

I’ve been lucky to have found a niche that excited me and that I’m suited to, but there are ways you can create your own luck. The most valuable thing for me was the work experience I gained during holidays. These months working exposed me to industry whilst I was still at university and gave me an insight into the potential work out there.

Summer work isn’t always easy to come by and I applied to 30 or 40 engineering internships before securing one. I’d also recommend that everyone take a look at the smaller companies- they can often be the ones offering something a little more interesting and innovative. Because they’re smaller you have the potential to make more of an impact, be more involved and see more of the company.

Finally, always look at what funding opportunities might be out there. Getting financial support for the valuable work you are doing can allow you to pursue things in much more detail and continue your academic education at the same time as helping industry - which can ultimately be to the benefit of you personally, the company you are working with and the economy in general.

Patrick is completing an engineering doctorate at UCL while working at Lindstrand Technologies, supported by an Industrial Fellowship from the Royal Commission for the Exhibition of 1851. If you are looking for funding to develop innovative technology for a PhD or EngD with industry, learn more about the Commission’s Fellowship programme here.

For more student careers news and advice follow us on Twitter and LinkedIn

Nanogenerator consumes CO2 to generate electricity

Nice to see my my views being backed up by no less a figure than Sabine Hossenfelder https://youtu.be/QoJzs4fA4fo