Hybrid propulsion for helicopters

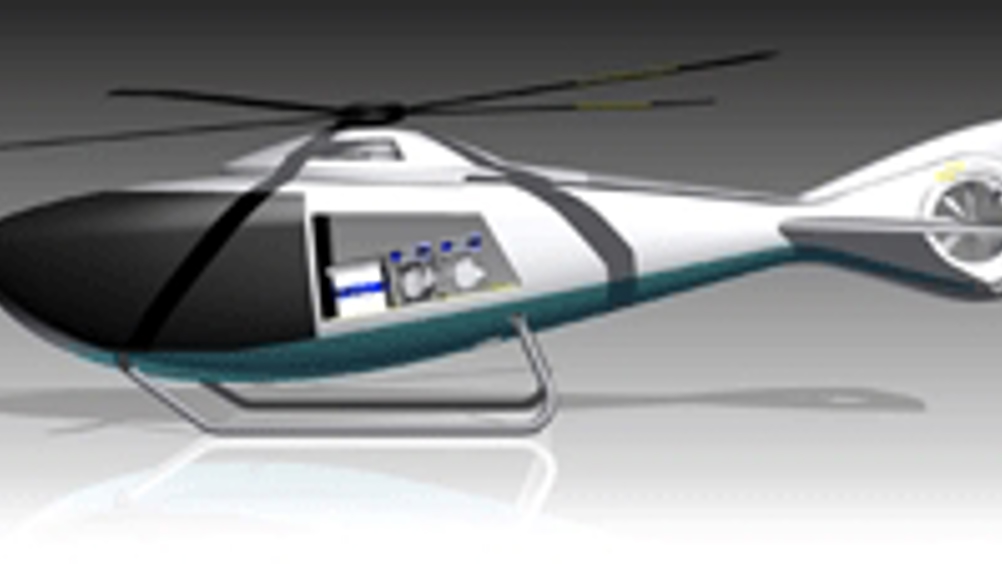

EADS has presented a diesel-electric hybrid propulsion system for helicopters at the ILA Berlin Airshow that promises to make the aircraft more fuel efficient and environmentally friendly.

Developed by EADS Innovation Works, the corporate research and technology network of EADS, the Eco2Avia research platform is expected to open up new possibilities for cleaner, safer and more quiet helicopter and aviation operations.

According to EADS, highly efficient electrical motors driving the rotors, combined with diesel engines, reduce fuel consumption and emissions by up to 50 per cent and take-offs and landings are possible on electrical power alone, resulting in lower noise levels and improved flight safety.

The main components of this patented hybrid system are multiple diesel-electric motor-generator units, a pair of high-performance batteries and a power electronics unit controlling the energy flows for best efficiency.

The OPOC (Opposed Piston, Opposed Cylinder) diesel engines are claimed to offer a fuel economy improvement of up to 30 per cent compared with today’s helicopter turbine engines.

The OPOC engine’s power output shafts are fitted with advanced, weight-optimised generators delivering electrical current to the power electronics unit. This unit manages the distribution of the electricity to the electrical motors driving the main rotor and the tail rotor, to and from the batteries as well as to the other user systems on the helicopter.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...