Chiltern Railways is helping to test the powertrain demonstrator as part of a wider powertrain competition funded by RSSB and Artemis Intelligent Power.

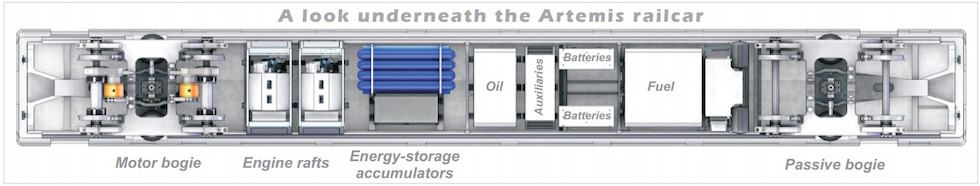

Project partner JCB will supply a diesel engine to power Artemis’s E-dyn 96 Digital Displacement hydraulic pump. The pump will supply flow to axle-mounted Digital Displacement motors and the transmission will be installed in a Chiltern Trains Driving Van Trailer.

The Digital Displacement Hybrid Rail Transmission project aims to reduce fuel consumption and improve engine performance by combining hydrostatic transmission with on board energy storage in the form of hydraulic accumulators, which store energy during braking for reuse during acceleration.

Stored energy can be reused to supplement engine power, reducing journey times through faster acceleration allowing trains to leave stations without producing emissions.

In use, the technology could be applied to non-electrified rail routes where electrification is difficult to justify on an economic basis.

According to RSSB, it also has the potential to provide benefits to the customer experience and to train planners in terms of reducing station dwell and journey times. The hybrid drive train can also be combined with a downsized engine to reduce the emissions and fuel consumption of the fleet.

Artemis Intelligent Power is testing the new solution on one of Chiltern Railways' Mark 3 DVT vehicles. The test will take place for three months, starting in December 2017.

First seven members join NG’s Great Grid Partnership

Agreed. It is all pretentious posturing and trite branding with no meaning or gravitas. Prepare to be disappointed by all of these greats/grates.