Researchers at the Environmental Molecular Sciences Laboratory (EMSL) at the US Pacific Northwest National Laboratory have developed an environmentally-friendly way to make nanostructures.

Taking a cue from nature, collaborators from the

By controlling solution freezing rate, nanoparticle concentration and storage temperature, the team’s ice mould method can be used to produce nanostructures with tailored shapes and sizes.

The team’s green chemical method was made possible by two natural phenomena: solute rejection and self-assembly. Upon freezing, aqueous solutions force out, or reject, impurities because they cannot be accommodated in the rigid lattice structure of ice. Depending on the freezing conditions, ice does not form a perfect lattice throughout. Rather, it has tiny pockets and channels. It is into these voids that impurities, in this case cerium oxide nanoparticles, become trapped together and can self-assemble.

After freezing cerium oxide nanoparticles in solution at different temperatures and rates and storing the frozen solution for days to weeks, the research team used transmission electron microscopy and other tools to characterise the resulting nanostructures.

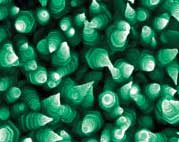

They observed that cerium oxide nanoparticles trapped in channels in the ice formed nanorods, and those trapped in larger voids formed octahedral superstructures. The team’s experimental observations were consistent with molecular dynamics simulations of nanoparticle behaviour under geometrically constrained conditions.

Many existing processes to manufacture nanomaterials use high molecular weight surfactants and solvents such as toluene, often generating chemical waste. The new method could be used to produce nanostructures in a more environmentally-friendly way as well as being less expensive than the more traditional manufacturing techniques.

TEM image of a cerium oxide nanorod formed in an ice channel

Nanogenerator consumes CO2 to generate electricity

Nice to see my my views being backed up by no less a figure than Sabine Hossenfelder https://youtu.be/QoJzs4fA4fo