The ChemCycling project involves BASF transforming domestic plastic waste into pyrolysis oil using a thermochemical process. The pyrolysis oil then replaces fossil fuels as the feedstock for creating new plastic products. According to BASF, the process can use plastics that would otherwise be unsuitable for recycling, such as multi-layer films or plastics with residues. The resulting material can also be tempered and coloured, making it a good replacement for the dashboard and exterior components that are often produced using virgin plastics.

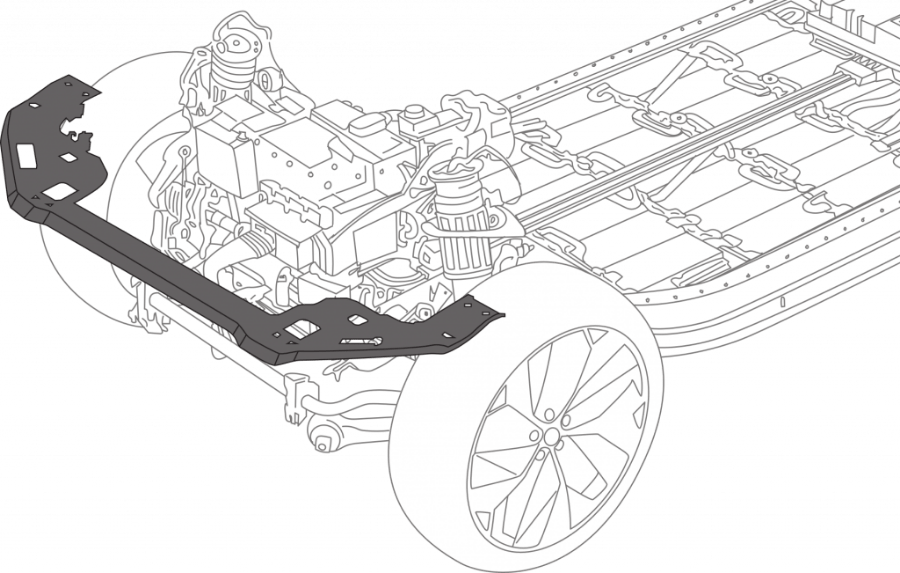

Jaguar Land Rover and BASF are currently testing the pilot phase material in a Jaguar I-Pace prototype front-end carrier overmoulding to verify it meets the same safety requirements of the original part. If successful, ChemCycling parts could begin to replace a host of plastic components across JLR’s range of vehicles.

“Plastics are vital to car manufacturing and have proven benefits during their use phase, however, plastic waste remains a major global challenge,” said Chris Brown, senior sustainability manager at JLR. “Solving this issue requires innovation and joined-up thinking between regulators, manufacturers and suppliers.

“At Jaguar Land Rover, we are proactively increasing recycled content in our products, removing single-use plastics across our operations and reducing excess waste across the product lifecycle. The collaboration with BASF is just one way in which we are advancing our commitment to operating in a circular economy.”

Alongside JLR, BASF is also working with several other partners as part of the ChemCycling programme, including customers in food packaging, insulation and refrigeration. BASF gets the pyrolysis oil feedstock for these pilot products from German partner Recenso. It breaks down or “cracks” this raw material at temperatures of around 850 degrees Celsius, with primary outputs of ethylene and propylene. These chemicals are then used to make a variety of chemical products. Under the mass balance approach, the share of recycled raw material can be mathematically allocated to the final certified product and each customer can select the allocated percentage of recycled material.

“A responsible use of plastics is crucial to solve the world’s waste problem,” said Dr Martin Brudermüller, CTO at BASF. “This applies to companies as well as to institutions and consumers. With chemical recycling we want to make a significant contribution in reducing the amount of plastic waste.”

Labour pledge to tackle four key barriers in UK energy transition

I'm all for clarity and would welcome anyone who can enlighten me about what Labour's plans are for the size and scale of this Great British Energy....