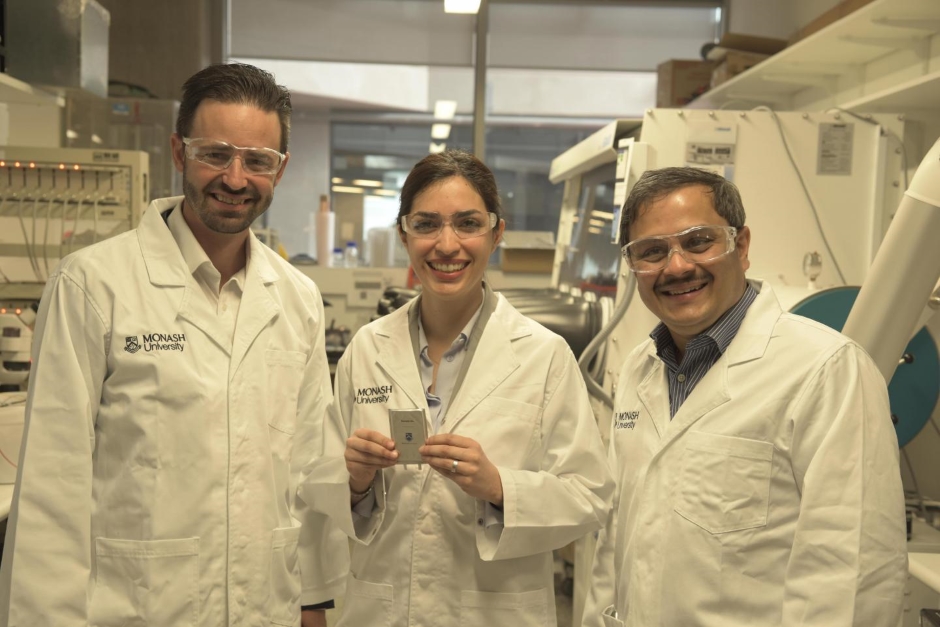

Dr Mahdokht Shaibani from Monash University's Department of Mechanical and Aerospace Engineering in Melbourne, Australia led an international research team that developed an ultra-high capacity Li-S battery that is claimed to have less environmental impact than current lithium-ion products. The study has been published in Science Advances.

The researchers have an approved filed patent - PCT/AU 2019/051239 - for their manufacturing process, and prototype cells have been fabricated by partners at the Fraunhofer Institute for Material and Beam Technology in Germany. It is claimed the battery can provide power to a smartphone for five days. Further testing in cars and solar grids is to take place in Australia throughout 2020.

Powerful lithium-sulphur battery inspired by the gut

Solid electrodes could unlock lithium-sulphur cell potential

"Successful fabrication and implementation of Li-S batteries in cars and grids will capture a more significant part of the estimated $213bn value chain of Australian lithium, and will revolutionise the Australian vehicle market and provide all Australians with a cleaner and more reliable energy market," said team member Professor Mainak Majumder.

"Our research team has received more than $2.5m in funding from government and international industry partners to trial this battery technology in cars and grids from this year, which we're most excited about."

Using the same materials in standard lithium-ion batteries, researchers reconfigured the design of sulphur cathodes so they could accommodate higher stress loads without a drop in overall capacity or performance.

Inspired by unique bridging architecture first recorded in processing detergent powders in the 1970s, the team is said to have engineered a method that created bonds between particles to accommodate stress and deliver a level of stability not seen in any battery to date.

Attractive performance, along with lower manufacturing costs, abundant supply of material, ease of processing and reduced environmental footprint make this new battery design attractive for future real-world applications, according to Associate Professor Matthew Hill.

"This approach not only favours high performance metrics and long cycle life, but is also simple and extremely low-cost to manufacture, using water-based processes, and can lead to significant reductions in environmentally hazardous waste, " he said in a statement.

Nanogenerator consumes CO2 to generate electricity

Nice to see my my views being backed up by no less a figure than Sabine Hossenfelder https://youtu.be/QoJzs4fA4fo