Additive manufacturing techniques are becoming increasingly established in the medical arena, with their ability to produce highly personalised objects proving invaluable manufacturing such things as hearing aids, dental crowns and implants, and components of prosthetics.

However, up until now use of the techniques has been limited to items which are rigid, or at least mostly so. Engineers from the Massachusetts Institute of Technology have been working on this problem, and have developed a process to make pliable 3D printed mesh materials whose flexibility and toughness can be tailored to support and emulate the soft tissues in the body such as muscle and tendon. Such structures might find utility as personalised supports for knees and ankles, or implantable supportive structures such as hernia meshes.

The research was carried out by post-doc mechanical engineer Sebastian Pattinson, who has since transferred to Cambridge University, and colleagues.

"3D-printed clothing and devices tend to be very bulky," Pattinson said. "We were trying to think of how we can make 3D-printed constructs more flexible and comfortable, like textiles and fabrics."

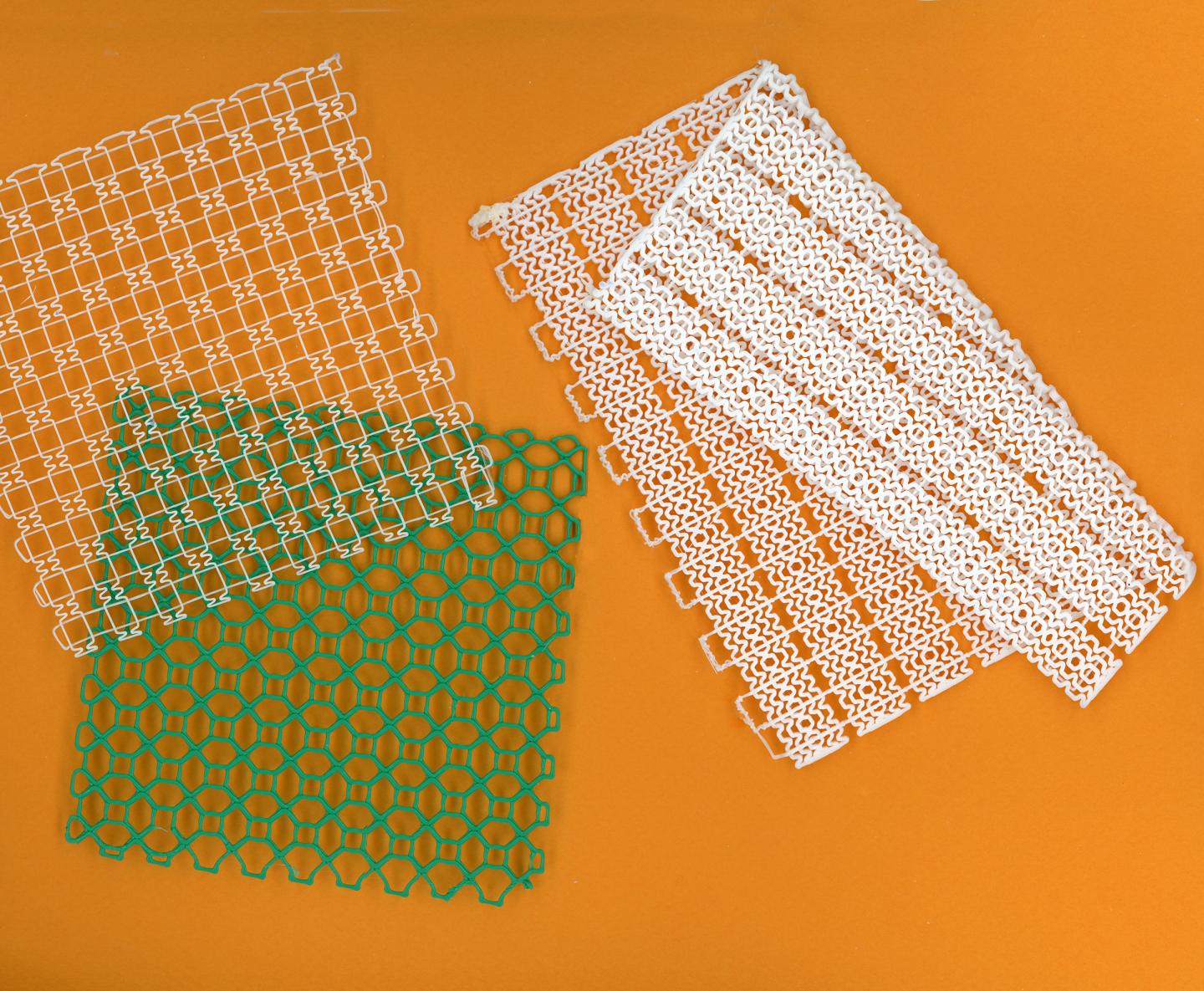

Pattinson was inspired by the molecular structure of collagen, and used that as a model for wavy patterns that he 3D-printed in a thermoplastic polyurethane. These patterns resembled the kinked intertwined strands that collagen forms in tissues in the body, which straighten as they stretch but are hard to extend when they become taut. He then fabricated a mesh configuration to resemble stretchy yet tough, pliable fabric. The taller he designed the waves in the printed patterns, the more the mesh could be stretched at low strain before becoming stiff. This design principle can help to tailor the degree of flexibility of the mesh, which helps it to mimic soft tissue.

The key to the properties of the mesh configuration is the way it is printed. In traditional 3D printing using heated polymers, each layer bonds to the layer below it because these materials are sticky when warm. Pattinson found that, once he printed a first layer, if he raised the print nozzle slightly, the material extruded will take a little longer to land on the underlying layer, giving it a little time to cool and become slightly less sticky. By printing a mesh pattern in this way, Pattinson created layers that rather than being fully bonded could move slightly relative to each other, and therefore could conform more easily to shapes underneath them.

This allowed the team to design meshes incorporating auxetic structures that have the property of becoming wider when put under tension. They designed an auxetic mesh, the centre of which becomes wider when stretched and conforms to the shape of a knee as it bends. "The beauty of this technique lies in its simplicity and versatility. Mesh can be made on a basic desktop 3D printer, and the mechanics can be tailored to precisely match those of soft tissue," said John Hart, an associate professor and co-author of the team's study detailing the research in Advanced Functional Materials.

The engineers printed a long strip of mesh and tested the support on the ankles of healthy volunteers. The test consisted of sticking a strip along the outside of the ankle in orientation which they’d had predicted would support the ankle if it turned inward. They then put the volunteer’s ankle into a stiffness measurement robot developed by Meghan Huber, another co-author. This robot, which went by the descriptive name of Anklebot, moved the ankle in 12 directions measuring the force exerted with each movement both with and without the mesh. In general, the team found that the mesh increases the ankle’s stiffness during inversion (inward turning) but did not affect movement in other directions.

To test the material further, the team also fabricated a knee brace design that could conform to the shape of the knee even as it bent. They also produced a glove with a 3D printed mesh sewn into its top surface to conform to the wearer’s knuckles, which could be used by somebody who had suffered a stroke as this often causes the hand to clench uncomfortably and involuntarily.

Implantable meshes might benefit from incorporating a stiffer material into the fabric. To this end, Pattinson’s team developed a way to print stainless steel fibres over regions of elastic mesh where stiffer properties would be needed, and then printing another elastic layer on top of the steel to sandwich the stiffer threads into the mesh. This would allow it to stretch easily up to a point, after which it would stiffen to provide stronger support to prevent muscle from overstraining.

“There's potential to make all sorts of devices that interface with the human body," Pattinson said. Surgical meshes, orthoses, even cardiovascular devices like stents - you can imagine all potentially benefiting from the kinds of structures we show."

Poll: Should the UK’s railways be renationalised?

Presumably the political fallout would be that the rail users would complain that they were being taxed unfairly to subsidise the people going about...