Metal fatigue reduced through nano-engineering

Researchers from Brown University and the Chinese Academy of Science have shown how metal fatigue can be mitigated by ‘nanotwinning’ its structure at the atomic level.

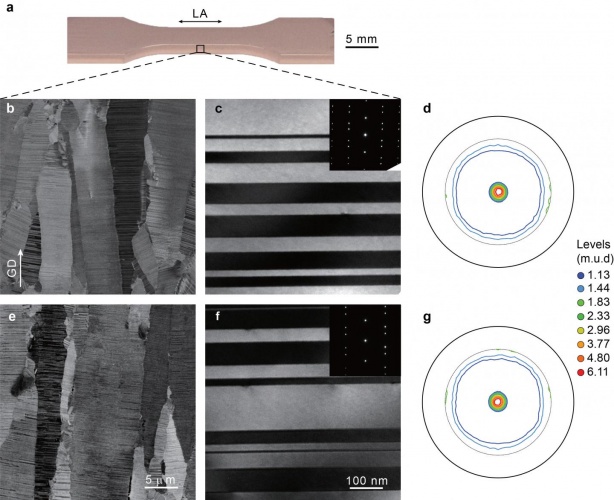

Electron microscope images show that the microstructure of the material before the tests (images b and c) were preserved after 17,000 loading cycles (Credit: Pan et al)

The study, published in the journal Nature, details how fatigue is reduced when tiny linear boundaries in a metal's atomic lattice line up in complimentary pairs known as ‘nanotwins’. Under repetitive strain, the nanotwins deform into linear bands called correlated necklace dislocations. The dislocations remain parallel to each other and don't block each other's motion, meaning the effects of the dislocations are reversible and fatigue is diminished.

"In a normal material, fatigue damage accumulates because dislocations get tangled up with each other and can't be undone," said Huajian Gao, a professor at Brown University's School of Engineering and corresponding author of the paper.

"In the twinned metal, the correlated necklace dislocations are highly organised and stable. So when the strain is relaxed, the dislocations simply retreat and there's no accumulated damage to the nanotwin structure."

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...