Nanowire organisation method could mean cheaper screens

Duke University chemist Ben Wiley and his graduate student have developed a technique to organise copper atoms to form long, thin, non-clumped nanowires.

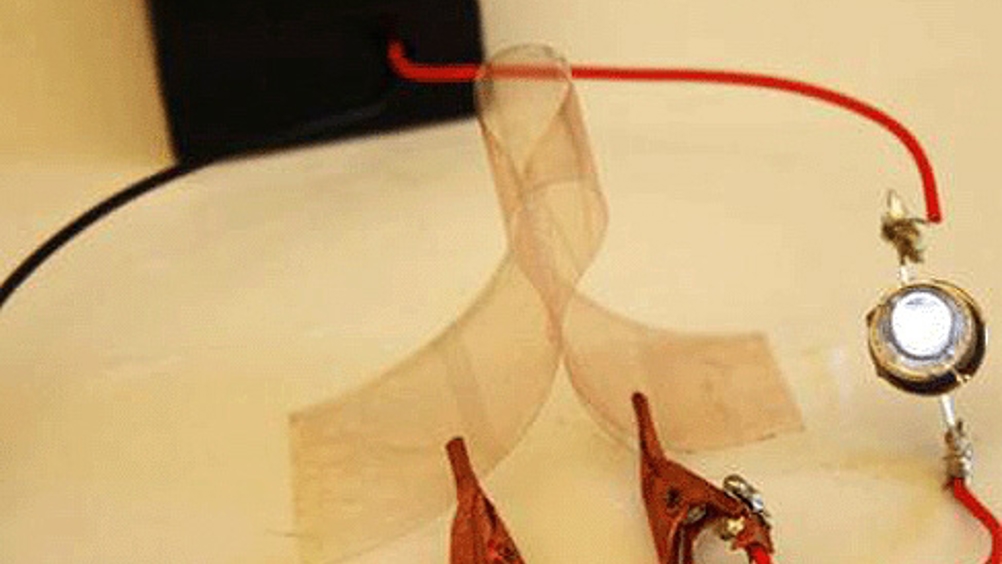

The nanowires are then transformed into transparent, conductive films and coated onto glass or plastic for applications in displays on mobile phones, e-readers and iPads. They could also be utilised to build foldable electronics and improved solar cells, according to new research.

According to Duke University, the research shows that the copper nanowire films have the same properties as those currently used in electronic devices and solar cells, but are less expensive to manufacture.

The films that currently connect pixels in electronic screens are made of indium tin oxide (ITO). It is highly transparent, which transmits the information well. However, ITO film must be deposited from a vapour in a process that is reportedly slow and, once the ITO is in the device, it cracks easily. Indium is also an expensive rare-earth element, costing as much as $800 (£512) per kilogram.

These problems have driven worldwide efforts to find less expensive materials that can be coated or printed like ink at much faster speeds to make low-cost, transparent conducting films, Wiley said.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...