New form of carbon is tough and elastic

A joint US-China research team has discovered a new form of carbon that is ultra strong, yet elastic like rubber.

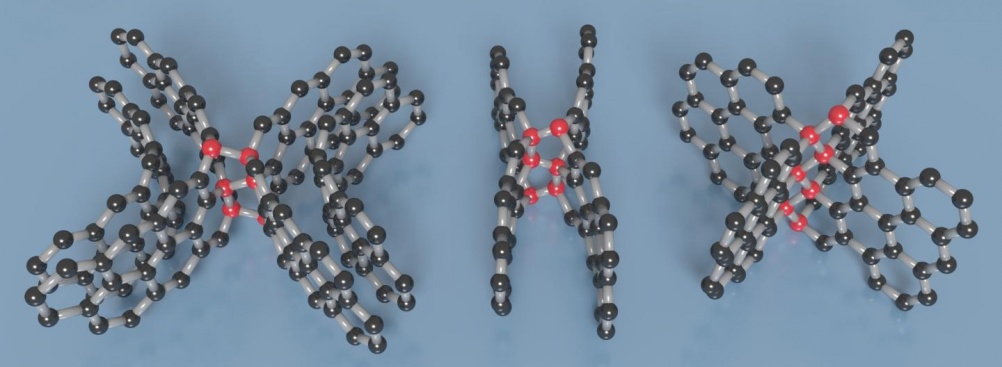

(Credit: Timothy Strobel)

Developed by engineers at Washington DC’s Carnegie Institute for Science and China’s Yanshan University, the material is also lightweight and electrically conductive. The researchers claim it could have a wide array of applications, ranging from aerospace engineering to military armour.

To create it, the team pressurised and heated a structurally disordered form of carbon called glassy carbon. This starting material was brought to about 250,000 times normal atmospheric pressure and heated to around 1,000 degrees Celsius. Under the high-pressure synthesis conditions, disordered layers within the glassy carbon buckle, merge, and connect in various ways, resulting in a form of carbon that exhibits traits of both diamond and graphite, two of carbon’s allotropes. The findings are published in the journal Science Advances.

"Light materials with high strength and robust elasticity like this are very desirable for applications where weight savings are of the utmost importance, even more than material cost," explained Zhisheng Zhao a former Carnegie fellow, who is now a Yanshan University professor.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...