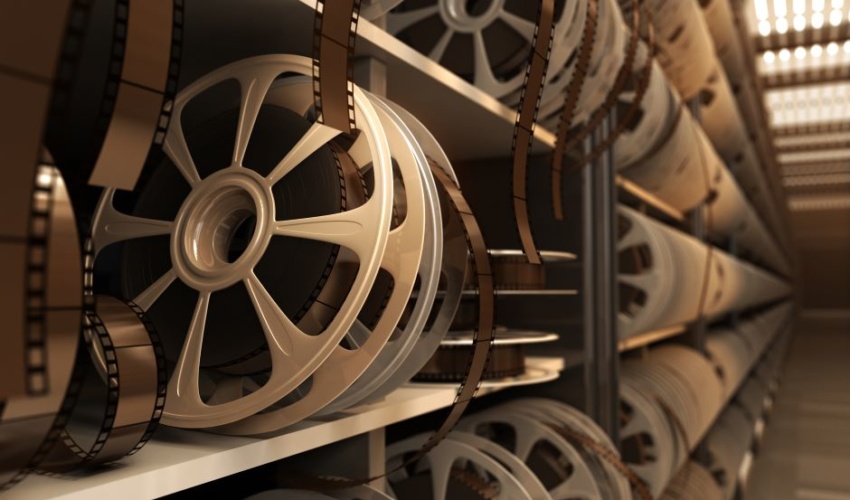

Large numbers of photographs, films, posters and slides produced between 1895 and 1970 were made using cellulose derivates that degrade in the presence of acetic acid.

C2I 2019: Sustainable manufacturing at world’s largest nanomaterials plant

Promethean Particles partner in water repellent fabrics project

Utilising its continuous flow production process, Promethean is developing Metal Organic Frameworks (MOFs), which are highly porous materials that selectively adsorb the acetic acid. Today, many artefacts are stored in archives or boxes which do not offer adequate protection.

In a statement, Promethean Particles’ research scientist Charles Toft said: “When acetic acid is produced, it accelerates the degradation of the artefact even further and, once started, this damage is irreversible. Thousands of photographs, films, posters and slides are lost forever because of this damaging process.

“We are working with organisations from across Europe, as part of the NEMOSINE project, to develop innovative packaging solutions that will overcome the challenges that storing documents and artefacts over long periods of time presents.”

The NEMOSINE project has received funding from Horizon 2020 and is made up of 16 partner organisations.

Promethean is working with another project partner that produces MOFs with the required functional properties via a lab-scale batch process. Promethean adapts the batch method onto its continuous flow reactor systems to manufacture MOFs with the same, or similar, functional properties and facilitate upscaling.

Initial performance testing is said to have generated positive results and Promethean is now focused on scaling up the manufacturing process to produce larger quantities, validate the material, and ensure the solution will be commercially viable.

Toft said: “Promethean operates a market-disrupting continuous-flow production process meaning the MOFs are reproducible on a large scale, without affecting performance and quality. By achieving economies of scale in production, we can support the commercial viability of the project’s results.

“Importantly for Promethean, the MOFs being developed can also be utilised in other applications such as chemical filtration and separation within a wide range of industries, so the commercial opportunities opening up as a result of this work are really quite exciting.”

In addition to the research by Promethean, other NEMOSINE partners are developing sensors to detect oxygen and humidity levels, as well as anti-fungal agents, to prevent microbial build-up during archived storage.

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...