Royal Mint to build plant for turning e-waste to gold

The Royal Mint has announced plans to build a world-first plant in South Wales to recover gold from electronic waste.

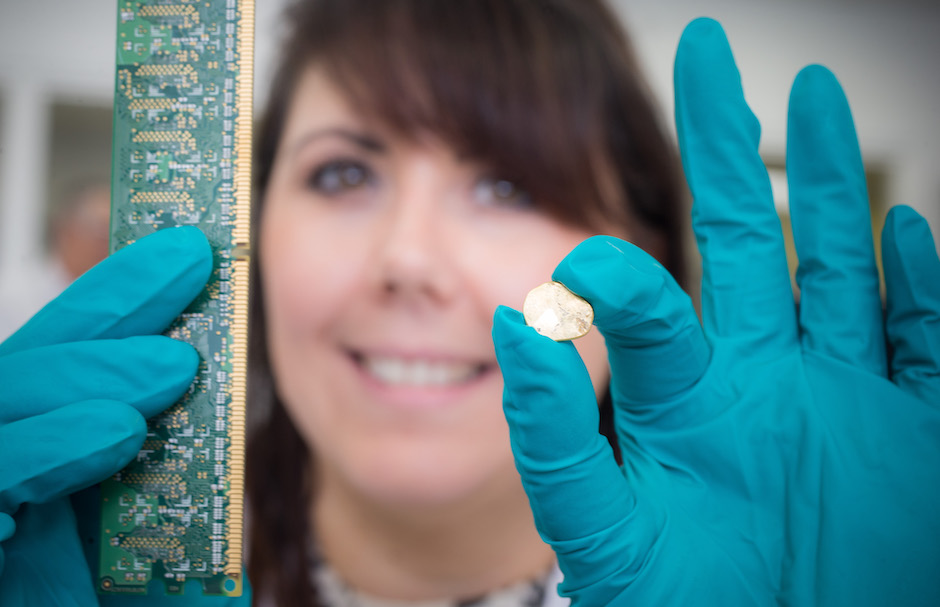

The development follows its recently announced partnership with Canadian tech start-up Excir, whose patented technology is said to be capable of recovering over 99 per cent of the gold within circuit boards of laptops and mobile phones, selectively targeting the metal in seconds.

The facility aims to help address a growing environmental issue, support jobs and skills in Britain, and create a new source of high quality precious metals for the business.

Construction of the plant begins this month. It will be located within The Royal Mint’s site and, when fully operational in 2023, is expected to process up to 90 tonnes of UK-sourced circuit boards per week.

This will generate hundreds of kilograms of gold per year, and is expected to support around 40 jobs, helping existing employees to reskill as well as recruiting new chemists and engineers.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...