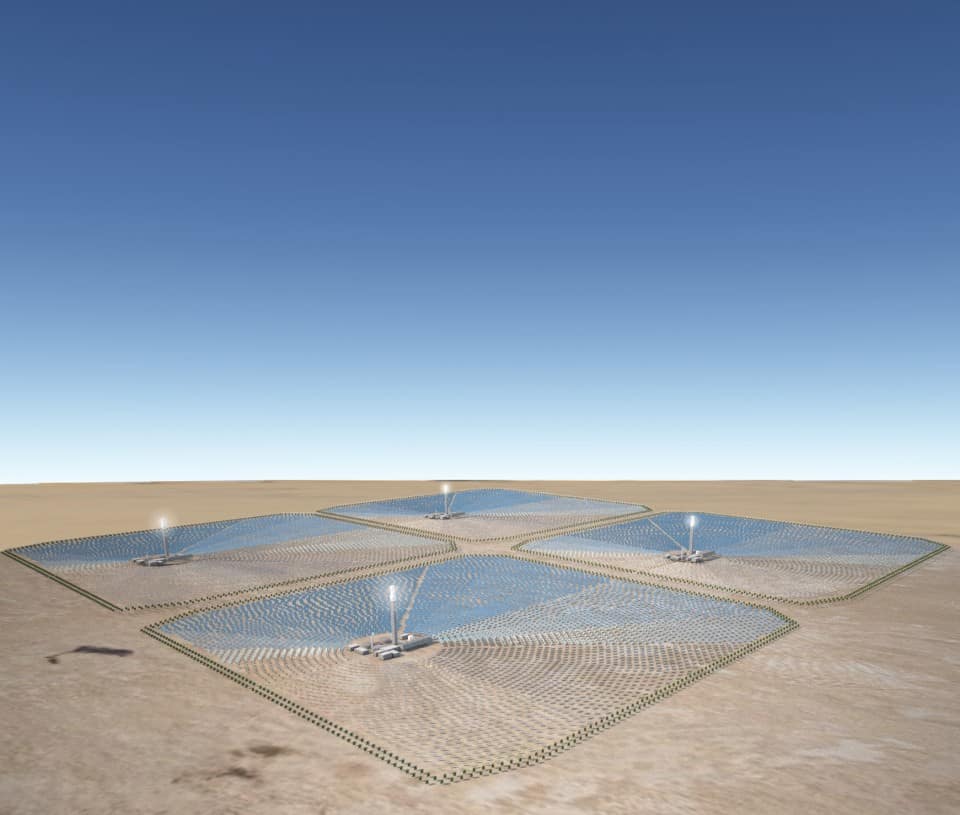

The research is claimed to advance global efforts to design hybrid systems that combine solar photovoltaic cells, which convert visible and ultraviolet light into electricity, thermoelectric devices that convert heat into electricity, and steam turbines to generate electricity. The thermoelectric devices and steam turbines would be driven by heat collected and stored using mirrors to focus sunlight onto a selective solar absorber and reflector.

To efficiently collect heat from the sun, specially designed surfaces based on low-cost materials are needed to selectively absorb photons from a certain range of the light spectrum while reflecting others.

“The key point is that to capture sunlight as efficiently as possible you have to do two things that compete with each other: one is to absorb as much power from the sun as possible, but secondly, not reradiate that power,” said Peter Bermel, lead researcher and assistant professor in Purdue University’s School of Electrical and Computer Engineering.

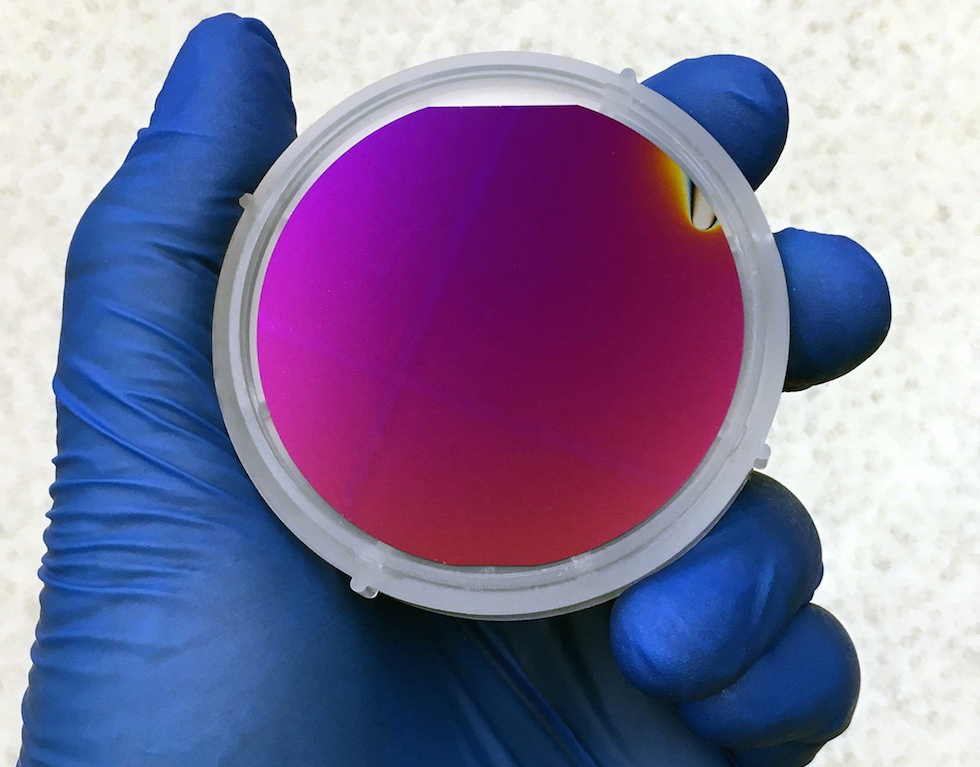

“In this study, we use off-the-shelf silicon wafers as a platform to design, fabricate, and characterise a structure capable of absorbing lots of sunlight, without re-radiating as much heat,” he said. “We add a layer on the top and bottom to give it greater ability to absorb sunlight, while also reflecting longer wavelengths.”

The team’s findings are detailed in a paper appearing online in Applied Physics Letters.

"This work shows that highly efficient solar thermal energy conversion can be achieved with very simple structures and common materials,” said graduate student Zhiguang Zhou. “This is a key step towards real applications, and we hope that it will inspire more efforts along this track."

The silicon solar device contains an upper layer of an anti-reflection coating made of silicon nitride and a back reflective layer made of silver.

An added complication is that properties of the material change dramatically while going from room temperature to around 500 degrees Celsius. Extending previous work by researchers, the team developed a detailed model that simulates how the material properties change with rising temperature. The model helped researchers design the structure built from silicon wafers, and led to the discovery that a selective absorber made of thin films of silicon can exhibit even higher performance.

The flexibility of thin films offers potential advantages, since they can be applied to curved structures such as mirrored parabolic troughs used for concentrated solar power systems. The troughs track the sun, concentrating the sun’s energy by about 50 times.

“Not only do these thin films appear to have better performance, but they are very flexible, so you could coat any surface,” Bermel said.

The hybrid solar-power system would ideally achieve efficiencies of over 50 per cent, compared to 31 per cent for photovoltaic cells. The researchers estimate that with 50 times the sun's concentration produced with the parabolic troughs, it is possible to convert 51.5 per cent of sunlight into usable, high-grade heat at 490 degrees Celsius.

Future research will include work to study the flexible thin-film-based approach. The long-range goal is to incorporate all of the components into a working system for continuous generation of electricity in large-scale power generation and small residential systems.

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...