Without structural engineers, we would never have landed on the moon and had a successful Apollo 11 mission, says Tim Ibell - FREng FIStructE, chair of the 2019 Structural Awards judging panel and Professor at Bath University

Without structural engineers, we would never have landed on the moon and had a successful Apollo 11 mission, says Tim Ibell - FREng FIStructE, chair of the 2019 Structural Awards judging panel and Professor at Bath University

Part of the job of a structural engineer is to ensure that an object being designed for a specific purpose is strong and stiff enough for its purposes by combining an understanding of how to calculate stresses with an understanding of how much stress particular materials can withstand. A simple example would be a disposable plastic spoon. It needs to be made with the minimum amount of material to save resource, but it mustn’t bend too much, and it certainly mustn’t break in normal use. Have you ever noticed those little plastic stiffeners at the back of a spoon, connecting the shaft of the spoon to the curved bit? These are the clever interventions which structural engineers make in order to save material while providing good service.

50th anniversary coverage of Apollo 11

Of course, a spoon is a trivial example. Most structural engineers use their creativity daily on huge structures such as skyscrapers and bridges, where the ingenuity in the example of the spoon is repeated across all sorts of areas in such structures.

But now let’s go one step further. To space. There are all sorts of areas in space travel and space habitation in which structural engineers play an enormous role. It is perfectly true to say that without structural engineers, we would never have landed on the moon and had a successful Apollo 11 mission. Why? Because structural engineers had the prime responsibility of making the rocket light enough to be able to accelerate it out of our Earth’s gravitational pull, but stiff and strong enough to ensure that it didn’t buckle, collapse or warp out of shape under enormous stress. So, in other words, every gram of material on the rocket had to be useful to the structure or else it would have been wasteful. But which grams of material are useful and which are not?

You’ll recall a few days ago that we heard stories of rail track buckling in the heat wave we all enjoyed. This is a natural phenomenon. When things heat up, they expand. The rail track was experiencing a temperature increase from a usual 15 degrees Celsius, say, to around 38 degrees Celsius. A large increase, you might think.

Now consider space. During ‘night-time’ on the moon, where there is no atmosphere to moderate thermal fluctuations, the temperature is about -173 degrees Celsius. During ‘daytime’ on the moon, it is about 127 degrees Celsius. That is a swing of 300 degrees Celsius! That dwarfs anything we see on planet Earth, thankfully. But it means that structural engineers need to be able to design our satellites, rockets and space stations to withstand these sorts of fluctuations for times when they face the sun and for times when they are shielded from the sun. If rail track buckles on our planet when the temperature rises by 25 degrees Celsius, say, just imagine what could happen to our structures in space if we didn’t understand how to design them against structural collapse under massive temperature differences?

A typical hurricane exerts pressure on a structure of about 1% of ambient air pressure. But in space, where there is a vacuum, a rocket or space station which has internal air pressure to support life feels a force on it from the differential between the vacuum and the pressurised inside which is about 100 times more than a building would feel under a typical hurricane. The structure wants to burst apart under gigantic stress. So, the materials we use in space need to be extraordinarily strong and stiff. But remember that they must also be light, or else we couldn’t have blasted off in the first place.

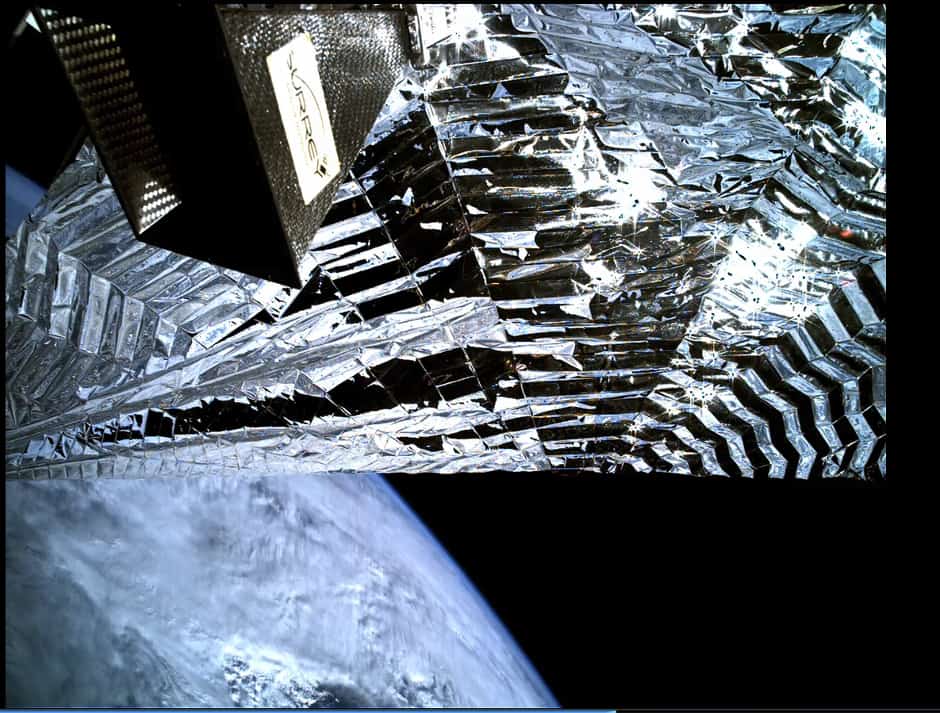

Finally, have you ever wondered how it is possible for large delicate satellites, with their big solar panels, to have been transported up into space in a rocket? Surely there isn’t enough space in a rocket for these huge structures? Yes, that’s right. There isn’t. So, structural engineers need to fold up these sorts of structures into tight packs, so that they fit into rockets, and then ‘deploy’ them when the rocket is in orbit. This means that these packages suddenly stretch their legs, so to speak, and deploy themselves into the vast satellite structures we see. The ability to control this process under fluctuating temperatures, remotely, relying on tiny electrically-driven machines is all part of the essential skills needed to engineer our structures in space.

This combination of ingenuity, creativity, and an understanding of just how close, or far, from a disaster we are in space, and indeed on our very own planet, is the job of the structural engineer.

Tim Ibell - FREng FIStructE, chair of the 2019 Structural Awards judging panel and Professor at Bath University

Nanogenerator consumes CO2 to generate electricity

Nice to see my my views being backed up by no less a figure than Sabine Hossenfelder https://youtu.be/QoJzs4fA4fo