Researchers at the Fraunhofer Institute for Manufacturing and Advanced Materials in Dresden have developed a titanium-based substance for a new generation of implants.

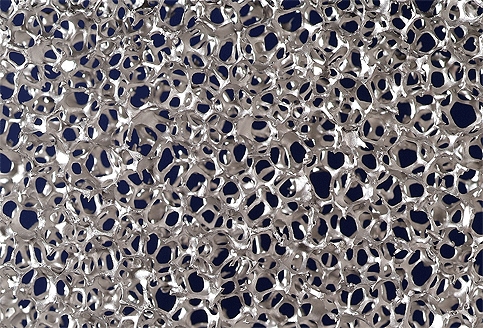

According to Dr Peter Quadbeck, the coordinator of the TiFoam research programme at Fraunhofer, the new porous material makes implants less stiff than conventional ones and promotes in-growth into surrounding bones.

Quadbeck said the titanium foam was developed through a powder-metallurgy-based moulding process that has been used for decades in the industrial production of ceramic filters for aluminium casting.

He explained that the process begins by coating polyurethane foams with a solution consisting of a binding medium and fine titanium powder. The polyurethane and binding agents are removed through vapourisation, and the resulting foam structure is ultimately sintered.

While there are titanium-based bone implants on the market, Quadbeck said they are often very expensive.

‘With our development we think it may be possible to manufacture such bone implant material with a much lower price,’ he said.

Quadbeck said implants made with TiFoam would be durable enough to sustain the forces of weight and motion. The implants would also have bone-like rigidity and this means that stress could be applied to them immediately after insertion.

While the TiFoam researchers concentrated on demonstrating the viability of titanium foam for replacement of defective vertebral bodies, the team claims that it is also suitable for repairing other severely stressed bones.

Apart from Fraunhofer’s role in the project, physicians from the medical centre at the Technical University of Dresden and several other companies were involved in developing the titanium foam.

Project partner Innotere stated that it would soon develop and manufacture TiFoam-based bone implants.

Nanogenerator consumes CO2 to generate electricity

Nice to see my my views being backed up by no less a figure than Sabine Hossenfelder https://youtu.be/QoJzs4fA4fo