UK car production down four per cent in October

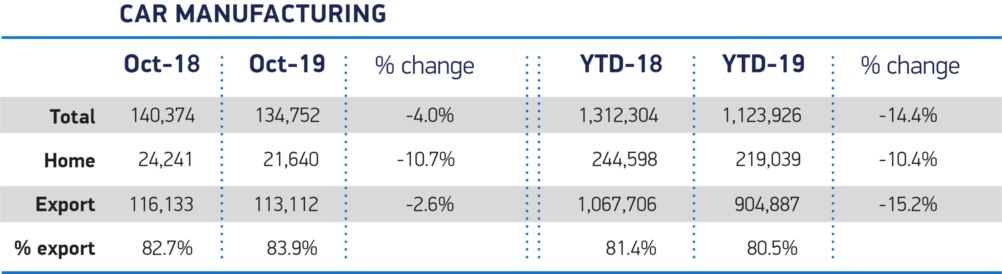

Figures released by the Society of Motor Manufacturers and Traders (SMMT) show UK car production fell by four per cent in October compared to last year.

According to the SMMT, 134,752 units rolled off production lines in October 2019, which was 5,622 fewer models than October 2018. That four per cent decline feeds into a year-to-date drop of 14.4 per cent, with automotive production declining in 16 of the last 17 months.

SMMT counts cost of ‘no deal’ threat

SMMT launches car industry Brexit aid package

“Yet another month of falling car production makes these extremely worrying times for the sector,” said Mike Hawes, SMMT chief executive. “Our global competitiveness is under threat, and to safeguard it we need to work closely with the next government to ensure frictionless trade, free of tariffs, with regulatory alignment and continued access to talent in the future.

“This sector is export led, already shipping cars to more than 160 countries, and in a period of unprecedented change a close trading relationship with the EU and preferential trading with all these other markets will be essential to keep automotive in Britain.”

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...