The proof-of-concept device from the University of California San Diego is a soft, stretchy patch that cools or warms a user's skin to a comfortable temperature and maintains it as the ambient temperature changes. It is powered by a flexible, stretchable battery pack and can be embedded in clothing. The work is detailed in Science Advances.

"This type of device can improve your personal thermal comfort whether you are commuting on a hot day or feeling too cold in your office," said Renkun Chen, a professor of mechanical and aerospace engineering at UC San Diego who led the study. "If wearing this device can make you feel comfortable within a wider temperature range, you won't need to turn down the thermostat as much in the summer or crank up the heat as much in the winter.”

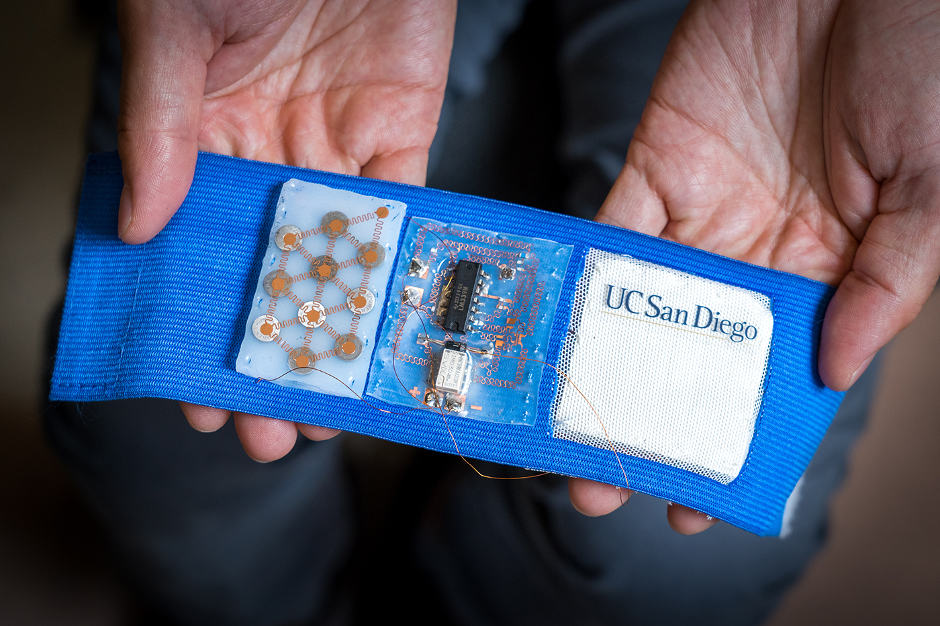

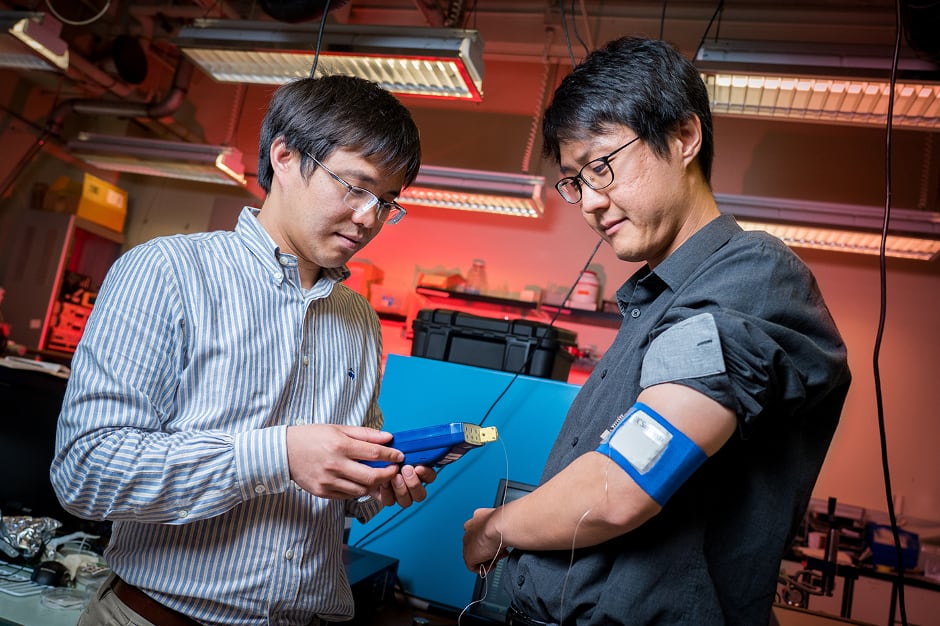

The patch is made of thermoelectric alloys sandwiched between stretchy elastomer sheets. The researchers embedded a prototype of the patch into a mesh armband and tested it on a male subject in a temperature-controlled environment. In two minutes, the patch cooled the tester's skin to a set temperature of 89.6oF and maintained this level as the ambient temperature was varied between 71.6 and 96.8oF.

The researchers built the patch by taking small pillars of thermoelectric materials made of bismuth telluride alloys, soldering them to thin copper electrode strips, and sandwiching them between two elastomer sheets that have been . specially engineered to conduct heat while being soft and stretchy. Researchers created the sheets by mixing Ecoflex (a silicone rubber material) with aluminium nitride powder.

The patch uses an electric current to move heat from one elastomer sheet to the other. As the current flows across the bismuth telluride pillars, it drives heat along with it, causing one side of the patch to heat up and the other to cool down.

One patch measures 5×5cm and uses up to 0.2W worth of power. Chen's team estimates that it would take 144 patches to create a cooling vest. This would use about 26W to keep an individual cool on an average hot day, climbing to 80W on days of extreme heat.

The team is now working on patches that could be built into a prototype cooling and heating vest. They hope to commercialise the technology in a few years.

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...