The key feature of the new composites is that they have a co-continuous structure comprised of two different materials with very different properties, creating a material combining the aspects of both.

In their experiments, the MIT researchers combined two polymer materials: one that was glass-like — strong but brittle; and another that was rubber-like — not so strong, but tough and resilient. The result was a material that was stiff, strong and tough.

Some existing composite materials, such as carbon-carbon composites that use fibres embedded in another material, can have great strength in the direction parallel to the fibres, but not much strength in other directions. Because of the continuous 3D structure of the new composites, their strength is nearly equal in all dimensions.

Edwin Thomas, materials science and engineering professor at MIT, said: ‘In most existing composite materials, the fibres form disordered mass with zero continuity, while the other material — typically a resin that fills the space and then hardens — is continuous and connected in three dimensions.

‘The material that forms the continuous structure tends to dominate the properties of the composite. But when both materials are continuous, you can get benefits that are surprisingly synergistic, not just additive.’

The next step in the research, Thomas said, is to make co-continuous composites out of pairs of materials whose properties are even more drastically different than those used in the initial experiments, such as metal with ceramic, or polymer with metal. Such composites could be very different from any materials made before, he added.

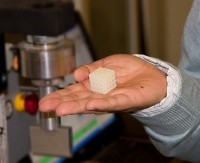

A sample of a co-continuous polymer composite material produced in the MIT laboratory

Glasgow trial explores AR cues for autonomous road safety

They've ploughed into a few vulnerable road users in the past. Making that less likely will make it spectacularly easy to stop the traffic for...