1. Industry 4.0 is going to be huge

The internet of things; the industrial internet; industry 4.0, call it what you will, there’s a growing consensus that the wireless connectivity of machines and the components that they make will herald a fundamental shift in the way that we manufacture products.

According to one of the firm’s championing the concept - German industrial giant Siemens, UK firms have traditionally been slow to adopt automation technology, but industry 4.0 is one technology trend that we can’t afford to ignore.

Fortunately, thanks to a collaboration between Siemens and the Manufacturing Technology Centre (MTC), British manufacturers will soon be able to view its benefits up close at the UK’s first Industry 4.0 demonstrator.

2. Ferrari is Italy’s biggest investor in high speed rail

Outlining to delegates some of the technologies that will be key to delivering high-speed rail in the UK, HS2’s technical director Andrew McNaughton, showed how engineers in other countries are turning to automotive expertise to help them crack the high-speed challenge.

One particularly intriguing example was Italy’s Ferrari-inspired 186mph Italo which has been connecting Milan, Rome and Naples since 2012. Indeed, according to McNaughton the iconic sports car manufacturer is Italy’s biggest investor in high-speed rail.

3. GB’s olympic Tae Kwon Do team tapped into aerospace expertise

BAE engineer Kelvin Davies, who heads up his firm’s UK sport technology partnership explained to delegates how an impact testing machine developed for the aerospace industry was used to monitor to analyse the electronic scoring vests that were used for the first time in the 2012 Olympics Taekwondo competition.

He explained that by monitoring the reaction of the vest to a range of different impacts, BAE was able to give the team vital information on optimal strike areas, and best angles of attack. And Jade Jones went on to win one of Team GB’s most memorable gold medals.

4. Everybody wants a slice of the JLR pie

From the conference theatre, to the exhibition floor and the hotel bar, everyone was talking about Jaguar Land Rover – and how the firm’s success in recent years is creating plenty of work further down the supply chain.

With more product launches planned over the coming years, JLR’s impact on the wider UK automotive sector looks set to continue, but the firm’s purchasing risk manager Michael Mychajluk warned suppliers that they will need to become more flexible as products become more diverse.

Click here to read our 2012 interview with JLR’s chief engineer, Bob Joyce

5. Mass personalisation will become as economical as mass production

From the automotive industry to the pharmaceutical world, consumers are demanding ever-greater levels of personalisation. But whilst bespoke products have traditionally come at a cost, a host of emerging technologies and approaches - will make large production runs of unique products as economical as large production runs of identical products.

The firms that ensure they’re in a position to cater for mass personalisation will be the manufacturing success stories of the future.

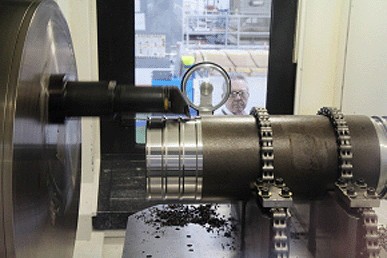

6. Most manufacturers only use 5 – 10 percent of a machine tool’s capability

The capabilities of today’s most advanced machine tools are truly impressive, but according to Rolls-Royce global manufacturing director Hamid Mughal most manufacturers are failing to exploit their full potential.

Outlining the opportunities for UK manufacturers to improve, Mughal argued that many firms are only using around 5 – 10 % of their machine tools’ capabilities. He said that by becoming more adventurous, deploying new techniques, and improving their understanding of issues such as resonance, manufacturers will be able to go “full blast”.

7. You’re not allowed to take rubber onto another planet

There are strict rules governing what you can and can’t take onto the surface of another planet and rubber – as an organic material – is on the list of banned substances.

This was one of the many problems facing the team of UK engineers behind the design and development of the robotic rover that will be sent to Mars as part of ESA’s ExoMars mission. Rubber was initially considered the ideal material form which to make a wheel capable of traversing the rocky Martian landscape.

But rubber wheels could leave traces of organic matter that future missions might misinterpret as a sign of life so the team had to develop an artificial material with many of the same properties.

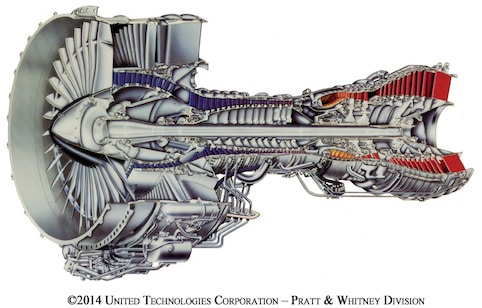

8. There’s plenty of life left in the jet engine

Today’s jet engines are most efficient devices ever invented for turning chemical energy into propulsive power but, according to the technology chief of one of the sector’s biggest manufacturers, there’s much more to come.

As civil aviation continues to grow, and environmental regulations become ever more stringent, the pressure is on for manufacturers to build more efficient engines.

But according to Alan Epstein, Pratt & Whitney’s VP of technology and environment, a new generation of ultra high bypass geared turbofans, and the advent of biofuels with energy density equivalent to kerosene, will help propel the industry to once-unthinkable levels of energy efficiency.

9. We are now mining landfill sites.

The idea of mining landfill sites for precious metals and fuels for power generation has gathered momentum in recent years.

But whilst the rise of the landfill mine is, in most respects a welcome trend the fact that we’re even having to consider doing it is also a stark illustration of mankind’s historically inefficient and shortsighted use of resources.

One potential way of breaking the cycle is through the so-called “circular economy” a model for an industrial economy in which materials and components are developed to be kept in use for as long as possible and to be recovered and regenerated at the end of their lives.

Many believe that embracing these kind of approaches will be critical if industry is to be resilient enough to cope with the unpredictable impact of climate change on global supply chains.

Poll: Should the UK’s railways be renationalised?

I think that a network inclusive of the vehicles on it would make sense. However it remains to be seen if there is any plan for it to be for the...