This is the aim of Dr Manuch Soleimani from Bath University’s department of electronic and electrical engineering who is leading the three-year Shell-Thick project to develop an induction tomography system for assessing the steel solidification process.

It aims to significantly improve the continuous casting process of steel by providing a real-time, non-destructive and reliable method of measuring the molten steel to detect any defects or fails as it solidifies and becomes a market product.

Induction tomography is an emerging non-invasive imaging technique already used in a number of applications, including medical diagnostics, geophysical exploration and civil engineering.

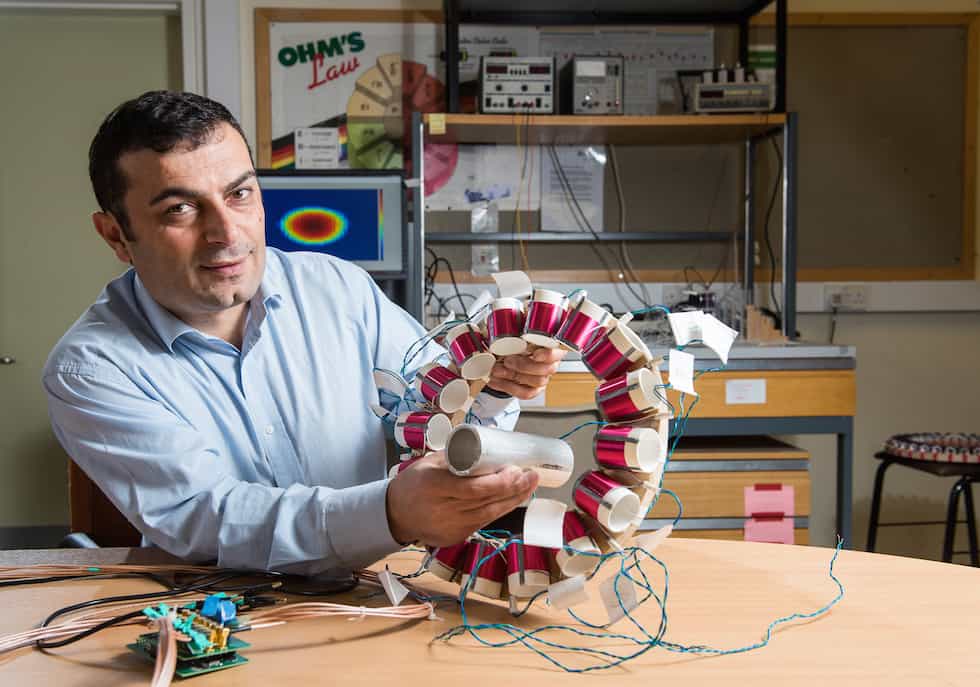

Soleimani, an associate professor at the university, told The Engineer: “Magnetic induction tomography attempts to image the passive electromagnetic properties of an object by measuring the mutual inductances between pairs of coils placed around its periphery.

“Measurements are acquired by passing an alternating current through excitation coils, producing a primary magnetic field.

“This magnetic field interacts with conductive and permeable objects in the medium to produce eddy currents, which, in turn, produce a secondary magnetic field, which is measured by sensing coils.

“As the secondary field depends on the materials present, the measured induced voltage is a non-linear function of the electrical and magnetic properties of the medium, that is, conductivity.”

The system will form a contactless bracelet around a billet of molten steel and take continuous measurements as the steel solidifies.

It will visualise the electrical conductivity of the different states of the solidifying steel and provide an image of its structural composition as it cools.

By enabling industry to continuously monitor and alter the cooling process, the technique should improve the quality, safety, productivity, costs and ultimately competitiveness of the UK and EU steel industries.

Soleimani said he and his team are pioneers in induction tomography and have already developed prototypes in the lab. A prototype would be tested at a factory later this year, he added.

During the project, Soleimani will work with the Fundacion Tecnalia Research & Innovation in Spain, as well as Italian steel industry companies Ferriere Nord and Ergolines Lab.

The project has been awarded a €1.4m (£1.1m) EU Horizon 2020 grant to help develop the technology.

Induction tomography would not solve the problems currently affecting the UK steel industry, but could help make it more competitive in the future, Soleimani said.

“Technology could enable us to be ahead in the production of high quality steel. Considering the cost of energy here and not having the subsidisation as China has, the only way to compete is having high quality products, and this is one step,” he added.

Labour pledge to tackle four key barriers in UK energy transition

I'm all for clarity and would welcome anyone who can enlighten me about what Labour's plans are for the size and scale of this Great British Energy....