Bioprinting breakthrough could lead to artificial tissues on demand

A specially adapted 3D printer has been used to create biomaterials from multiple sources, an advance that could lead to bioprinting complex artificial tissues on-demand.

The study, led by UCLA bioengineer Ali Khademhosseini, has been published in Advanced Materials.

“Tissues are wonderfully complex structures, so to engineer artificial versions of them that function properly, we have to recreate their complexity,” said Khademhosseini, who is UCLA’s Levi James Knight, Jr, Professor of Engineering at the UCLA Samueli School of Engineering. “Our new approach offers a way to build complex biocompatible structures made from different materials.”

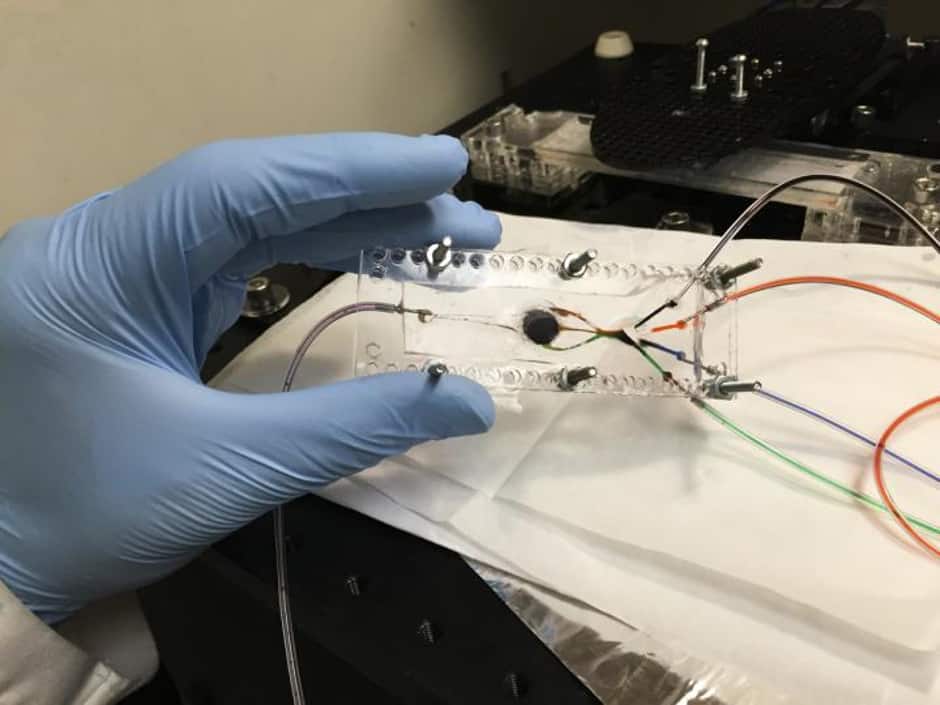

According to UCLA, the technique uses stereolithography and a customised 3D printer designed by Khademhosseini that has two key components. The first is a custom-built microfluidic chip with multiple inlets that “print” a different material. The other component is a digital micromirror, an array of more than a million mirrors that move independently.

The researchers used different types of hydrogels – materials that, after passing through the printer, form scaffolds for tissue to grow into. The micromirrors direct light onto the printing surface, and the illuminated areas indicate the outline of the 3D object that’s being printed.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

National Gas receives funding to develop Gravitricity underground hydrogen storage system

There can't possibly ever be a '<i>business</i>' case for the <i><b>bulk</b></i> storage of hydrogen, since Green hydrogen electrolysis...