3D printing with riboflavin creates polymer medical implants

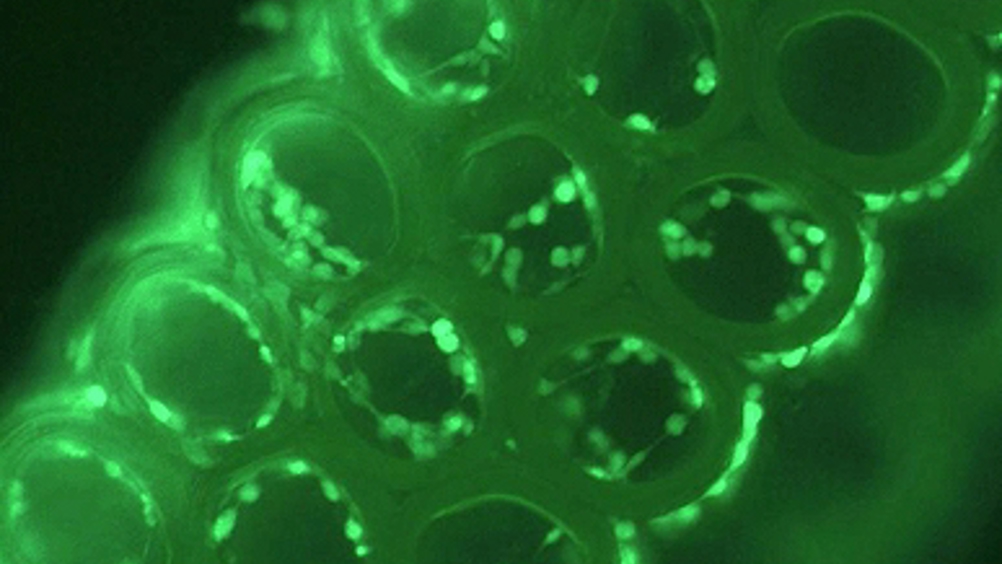

Researchers have discovered that riboflavin (vitamin B2) can be incorporated into 3D printing processes to create medical implants out of non-toxic polymers.

‘This opens the door to a much wider range of biocompatible implant materials, which can be used to develop customised implant designs using 3D printing technology,’ said Dr Roger Narayan, senior author of a paper describing the work and a professor in the joint biomedical engineering department at North Carolina State University (NCSU) and the University of North Carolina at Chapel Hill.

The researchers focused on a 3D printing technique called two-photon polymerisation, because it can be used to create small objects with detailed features, such as scaffolds for tissue engineering, microneedles or other implantable drug-delivery devices.

Two-photon polymerisation is a 3D printing technique for making small-scale solid structures from many types of photoreactive liquid precursors.

The liquid precursors contain chemicals that react to light, turning the liquid into a solid polymer. By exposing the liquid precursor to targeted amounts of light, the technique allows users to ‘print’ 3D objects.

According to NCSU, two-photon polymerisation has its drawbacks. Most chemicals mixed into the precursors to make them photoreactive are also toxic, which could be problematic if the structures are used in a medical implant or are in direct contact with the body.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...