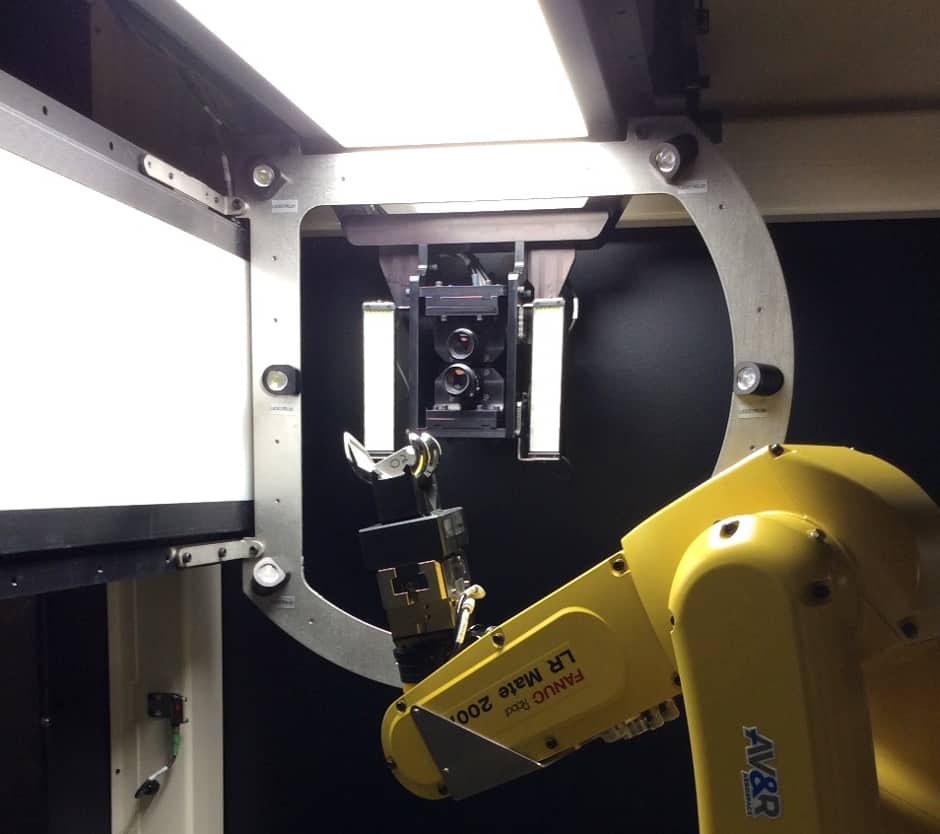

Researchers at AMRC are testing the automated visual inspection system, which has been developed by Canadian automation specialist AV&R, at its Factory 2050 facility.

The system uses a robot to handle a component that is lit from various angles. The robot rotates the component in front of a camera, to allow the system to obtain photometric data about its surface, and spot any tiny defects that might be present.

The technology allows a component, such as a turbine blade, to be lit in such a way as to mimic the way humans look at a surface, according to Harry Burroughes, senior project engineer in the AMRC’s Integrated Manufacturing Group (IMG).

“We’re trying to replicate the human ability to detect defects on a non-machined surface,” said Burroughes. “The human brain is actually very good at detecting anomalies.”

However, unlike humans, which can become tired or bored after a long shift, the robotic system can perform the process time after time, with the same level of accuracy and efficiency, he said.

What’s more, a robotic inspection system can be easily cloned if a company needs to increase its production capacity in a hurry, while employing a human operator to do the job is far more time consuming, said Burroughes.

“To train an operator for the inspection process can take around 18 months, whereas we can clone another machine quite quickly to increase a company’s rate capabilities.”

The machine was purchased with funding from the High Value Manufacturing Catapult. It could ultimately be used to inspect high-value metallic components, such as those used in the aerospace and medical industries.

As part of the trials, the team will be investigating how best to deal with the large amounts of data – around 15GB per part – that are generated by the system, including compressing it into a useable format.

They will also be looking at the use of augmented reality to present images of the components being inspected by the system to remote operators, said Burroughes.

“There might be borderline cases that need to be checked by a human operator, but that expert doesn’t necessarily need to be near the machine, they could be anywhere in the world,” he said.

Poll: Should the UK’s railways be renationalised?

I think that a network inclusive of the vehicles on it would make sense. However it remains to be seen if there is any plan for it to be for the...