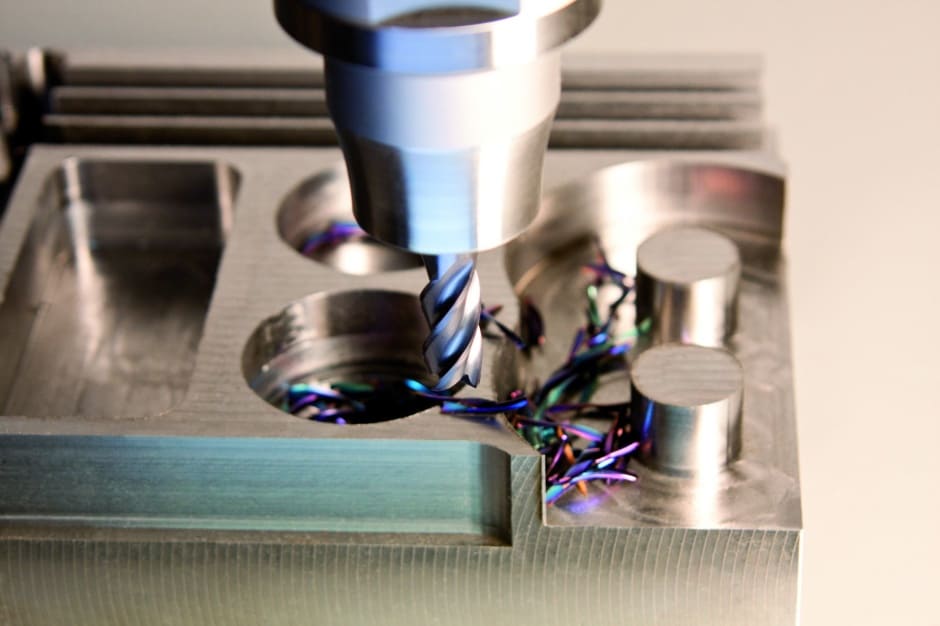

At the interface between a cutting tool edge and a metallic workpiece, the temperature can vary from 200°C to over 1,300°C. At such temperatures softer metals such as aluminium melt and the cut surface of the component can be damaged. However, with modern coatings and tool technology the expensive tooling is not badly affected by heat alone. It is thermal shock, or rapid temperature variations that weakens tools and this is far more likely to reduce tool life than simply exposing tools to high temperatures.

As Le Coz and Dudzinski at the LEM3 Research Centre at the Université de Lorraine explain, in a 2014 paper, “a moderate level of cutting-edge temperature and a low thermal shock reduces the tool-wear phenomena, and a low temperature gradient in the machined sub-layer reduces the risk of high-tensile residual stresses”.

In the majority of metal-machining operations, liquid coolant is still used to reduce temperature of both workpiece and tool and to evacuate chips from the cutting area. This amounts to hundreds of thousands of gallons of coolant fluid per year, and from £4 and more per litre, a lot of money.

The problem with using coolant for milling specifically is thermal shock. As the cutting edge engages with the workpiece and cuts the material, it generates friction and gets very hot during the cut. But as soon as the cutting edge is removed, coolant is poured on and instantly cools it, then the edge is immediately returned to the cutting operation and heats up.

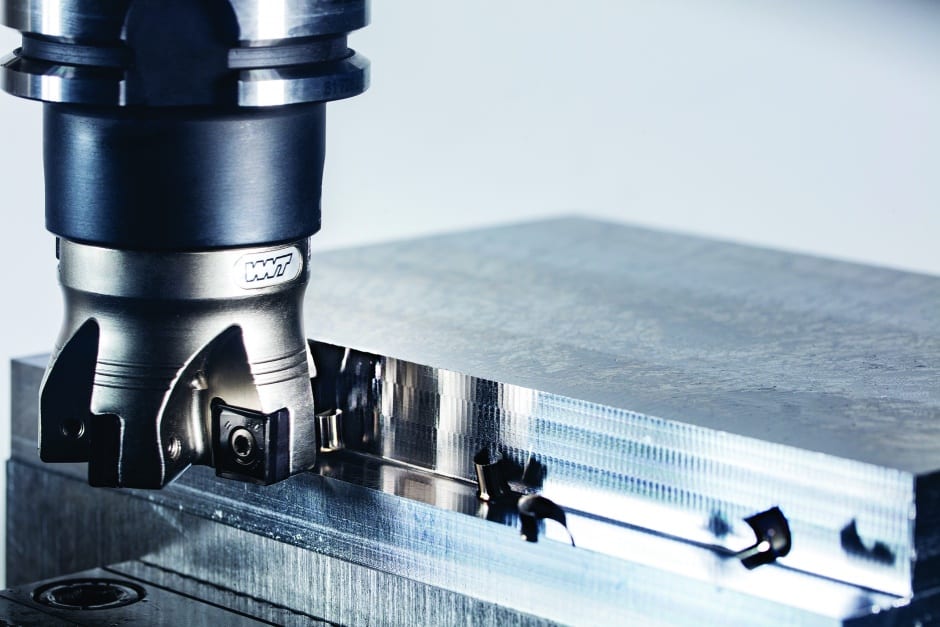

This is true, whether it is a solid tool or indexable insert. “You are getting hot-cold-hot-cold constantly at the cutting edge, which does not do the tool any good,” said Adrian Fitts, business development manager at WNT (UK). “This produces thermal shock and breaks down the cutting edge far quicker than allowing it to run hot full time.”

Dry machining is becoming more prevalent, in milling especially. In drilling, coolant is required because the tool has prolonged exposure to the material and fluid is essential to evacuate the chips. And dry machining in turning is rare as the cutting edge is constantly in contact with the workpiece, so without some cooling, the cutting edge will eventually fail. Milling is the main beneficiary.

“In milling applications, for example, cutting is always intermittent and the risk of thermal cracking caused by the coolant is even higher,” said Paul Campbell, product specialist at Sandvik Coromant. “Dry machining is therefore the primary choice to increase tool life, especially when cutting with steels, cast iron and some stainless materials.”

There are perhaps four main drivers of dry machining: removing the thermal shock cycle means extended tool life; the cost of coolant, where some subcontractors say the price is rising; waste coolant requires professional disposal, adding to cost; and operator health.

On operator health, WNT’s Fitts said: “Machine tools are becoming faster. At the speeds that spindles run at today, often the coolant just atomises. The operator is exposed to the atomised coolant on the tool changeover.”

Machine speeds are making dry machining more practicable. A generation ago a typical 150-200mm diameter face mill could be left running for more than an hour on a 10mm depth of cut, churning through at 200-300rpm. Although the heat produced was limited by low surface speeds, coolant was useful to keep the component cool while the tool was engaged with the piece for hours on end.

Today, machines are generally lighter and faster, with less torque, but that can’t be combined with depth of cut. So modern milling cutters tend to run with light depth of cut but very high speeds and feeds. Also, with faster speeds while the heat created is intense, each cut can be over very quickly. “Ten or 15 years ago on steel we would be running 140 to 150m per minute surface speed, wet [i.e. with coolant]. We are now running more like 230-280mpm, about double the speed, and dry,” said Fitts.

This high speed also helps avoid damage to the cut surface. “One mechanism is to cut really quickly so all the heat stays within the removed metal and doesn’t get in to the component,” said Prof Ken Young, technology director at the MTC.

High Sppeds and dry machining have been enabled by CNC control capability. NC controls have so much processing power they can control machines at very high feed rates and have the capacity for huge programmes. With CADCAM they can run very high speeds and feeds, but with no lagging. “One customer of WNT makes a component where the machine uses over one million lines of code, for one component,” said Fitts.

A sharper tool will keep a longer tool life. “We achieved 2.5 times the tool life with dry machining versus wet with the same tool and material. And it was running faster dry,” added Fitts.

Furthermore, after sintering of the insert and coating, the final operation is often now to polish the coating surface. This allows the hot swarf produced to flow over the surface of the coating more easily rather than sticking to it and generating more heat and friction. “The coatings developed for dry machining are to protect the tool, it acts as a heat shield between the hot chip produced by the cutting action and the carbide substrate,” said Fitts.

Another trend to promote dry machining and tool life is carbide technology. Carbide is becoming tougher and tends not to chip but wears. Operators can monitor and control a defined steady wear rate, but chipping is uncontrollable.

While dry turning is rare, some engineering companies use it. One Sandvik Coromant customer, a big producer of gears and shafts, does not apply any coolant because all its machines are fully automated and there is no manual handling of parts, so heat build-up is not an issue. “Also, the other typical benefits of using coolant – swarf control, surface finish and component quality – are not relevant to them as these parts are finished later in the process with CBN [cubic boron nitride],” according to Sandvik’s Campbell.

“Dry machining represents a more valuable alternative for them, especially in terms of environment sustainability and cost savings,” he added. “The choice between dry and wet machining depends therefore mainly on the type of machining, application, process and material our customers implement and adopt.”

And what about coolant savings? As well as a financial saving, there is also an environmental one. One company whose machines leaked coolant into an adjacent stream approached its tooling company to provide dry machining for them, to avoid further damage. However, coolant remains tremendously important for many engineering applications. “We have found that high-pressure coolant can have several benefits in surface finish and tool life, so there are counter-arguments and it’s still unclear to where the true benefits of dry machining lie,” said Adam Land, an application engineer at coolant supplier Jemtech.

UK Enters ‘Golden Age of Nuclear’

Apologies if this is a duplicate post - a glitch appears to have removed the first one: > While I welcome the announcement of this project, I note...