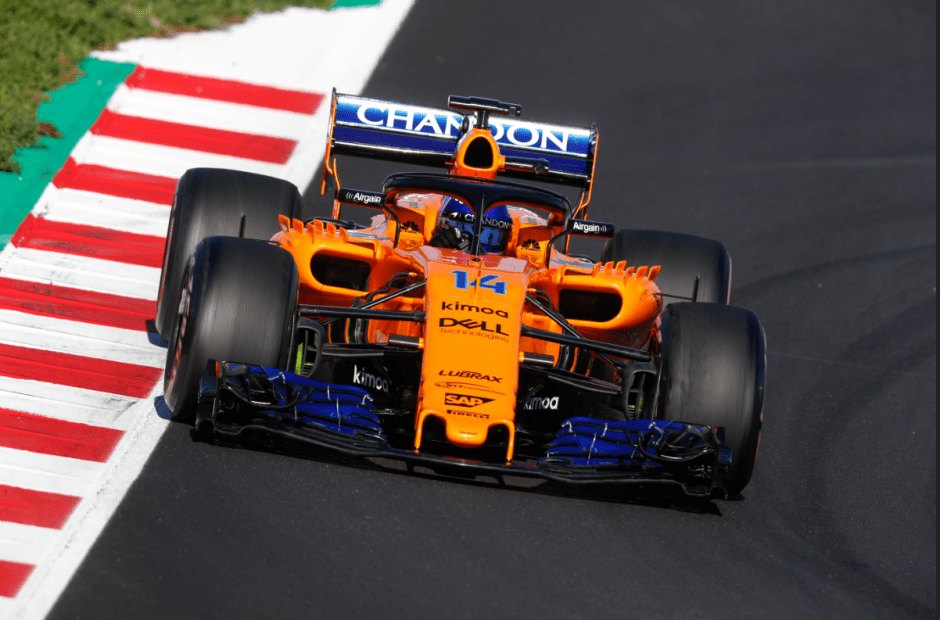

For some 20 weeks every year, Sunday is also Formula 1 day. Millions follow the races on television; the petrolheads may have some appreciation of the trackside and automotive technologies behind the speed and glamour, but possibly little appreciation of the manufacturing processes which underpin motorsport. There’s a reminder in the presence of the Haas brand on the grid, but machine tool technology is really a critical but unseen element of the infrastructure upon which all teams rely.

The relationship between Yamazaki Mazak and McLaren Racing provides a good example. Mazak has been the team’s exclusive supplier of CNC machine tools for 19 years; chief operating officer Simon Roberts says that over 12 per cent of the car is produced on its Mazak machines. McLaren’s Technology Centre has now taken delivery of three more machines: two full 5-axis VARIAXIS i-600 Multi-Tasking machining centres, and a QUICK TURN 250MY turning centre, taking the machine tool inventory up to 36.

This in-house capability helps tackle the changing rules within F1; in 2017, for example, McLaren changed every single Mazak-made part to comply with the new laws – with nearly 3,000 parts made in one week alone.

Producing in the UK

Heller, like Mazak, maintains machine tool production in the UK. Latest news from the company concerns the supply of a large, heavy-duty machine to GKN Aerospace Filton. A machine was required to complement existing capacity for rough-machining titanium aircraft components as GKN’s customer dramatically increased demand over two years, and the Heller H 16000, with a high-torque spindle was selected. Notwithstanding its size and rigidity, it weighs under 50 tonnes, so the location needed no special foundations.

GKN exploited the H 16000’s arrival to re-engineer a family of five structural aircraft components now being machined 24/7 from titanium forgings. The contract requires leaving a 3mm stock allowance ± 0.127mm over the entire surface of each part. None requires simultaneous milling in more than three CNC axes, so cycle time savings could be achieved on the 4-axis machine compared with the previous 5-axis process routes. For the largest of the five components (2,400mm by 200mm wide by 170mm), cycle time dropped from 70 hours across two operations to 52 hours, a saving of over 25 per cent. Similar reductions have been achieved on all parts, the smallest of which still requires 14 hours of machining.

Large workpieces are also the priority for the new DMC 1850 V vertical machining centre from DMG MORI, with 1,850mm x 700mm x 550mm axis travels and a maximum table load of three tonnes. Features include a one-piece cast iron bed, twin ballscrews in all axes and comprehensive cooling measures. The machine is designed to deliver high stability and extreme accuracy, including circularity of less than five microns, and so is suited to mould making and production of high-precision aerospace parts. Ergonomic operation is another feature of the machine, thanks to a door that opens to nearly two metres and a distance from the front of the machine to the centre of the table of just 677mm.

No swarf entanglements

Companies such as Astley Diamond Tools represent the other end of the machined component spectrum. This Birmingham-based business has invested in the latest Low Frequency Vibration (LFV) turn-mill technology from Citizen Machinery.

LFV is based on initiating selectable sequences programmed at the machine control through ‘G-codes’ to impart the size of chip to be produced. Within three months of installing the Cincom L20-VIII LFV, the company has transformed blank turning operations for its diamond tool production. Proprietor Ben Astley points to the example of a batch of 500 rotary diamond burrs, produced for a Polish customer, that are used to fettle cast iron. An ageing machine used previously had to be stopped every five or so parts to clear the tangled ‘bird’s nest’ of swarf.

“It would take at least 70 hours to produce the batch,” he says. “With LFV I complete the same order inside 16 hours. As swarf is chipped so finely, the only attention required is to change over the short bar feed and remove completed parts from the outfeed conveyor.” The investment has also enabled new markets, underpinning a competitive sub-contract small part turn-milling service. Investing in appropriate technology is critical for any successful subcontract business – the Accranut Company, along with its sister business Coventry Collets exemplifies this, having purchased several machines from XYZ Machine Tools. Both companies actually serve the machine tool industry, Accranut developing locknuts for use by machine tool companies; supporting machine builders with bespoke fixturing and workholding; and manufacturing machine parts that are no longer available as standard. Coventry Collets focuses on manufacturing collets and feed fingers. Machines from XYZ include the latest LR series vertical machining centre – from XYZ’s first range of Siemens-controlled vertical machining centres with linear rail technology.

Accranut’s CNC investment started in 2012 with two lathes and a bed mill, all using the ProtoTRAK control. Managing director Andy Davies comments on the latest move: “We had become so familiar with the ease of use of the ProtoTRAK control that I thought the next step was to bring in the XYZ 2-OP machining centre, (also ProtoTRAK control). However, after seeing a demonstration of an XYZ 750 LR vertical machining centre, the additional capacity swayed our decision. By adding a fourth axis rotary table as an option, we made further gains in capability.”

Cutting tool developments

Roughing turbine blades

Traditionally, button-style milling inserts have been selected for rough machining turbine blades. The limiting factor is that feed rates are relatively low using this style of insert. The development from Cutting Solutions by Ceratizit of the MaxiMill HFC-TUR milling system addresses this, doubling feed rates. The insert design’s large effective radius suits it to a variety of 3D machining applications and general face milling and its soft cutting action assists in cutting components with thin sections and large unsupported areas, such as turbine blades. The cutters can be used on lower-powered machines, that would not be suitable for high-feed milling style cutters.

ISO turning tools with

internal cooling

Ringwood-based Horn Cutting Tools has announced the availability of Boehlerit’s new turning toolholders with connections for internal coolant supply. They are available from stock with toggle clamp (ISO-P) and screw clamp (ISO-S) systems, allowing manufacturers to benefit from the productivity advantages of cooling directly at the cutting edge. The P variety is suitable for all ISO indexable inserts. There are no loose parts and only a few spares are required, making them easy to handle. Inserts can be clamped quickly and securely and released easily. Chip flow is smooth, as there are no obstructions. The S toolholders also enable the insert to be secured simply and safely, in this case using a cone-shaped positioning screw. Here too, chip flow is not compromised and a maximum of three spare parts is needed. In both cases, the coolant is supplied at the back of the shank end as standard or from below the head as an option.

Insert-based high feed

turning system

Sumitomo Electric Hardmetal’s High Feed Turning (HFT) system is said to deliver higher productivity hard turning at higher speed and feed rates. Performance is based on the more economic use of a specific design of octagon insert incorporating special wiper geometry, which enhances surface finish. Based on cubic boron nitride (CBN) insert technology, HFT hard turning trials have provided 12 to 16 times faster processing times over existing methods while enabling existing manufacturing surface finish and tolerances to be maintained. Also, insert life was doubled aided by the availability of eight cutting edges from the CBN insert.

Water Sector Talent Exodus Could Cripple The Sector

One possible reform to the Asset Management Plan (AMP) system would be to stagger the five year cycle across the ten or so water businesses, so that...