Added value: the rise of multifunctional 3D printing

UK-led advances in 3D printing could one day lead to techniques able to produce entire electronic devices in one shot. Jon Excell reports

It’s fair to say that over the past few years much of the hype surrounding 3D printing has given way to a more considered and sensible notion of where the technology fits in.

While not so long ago some warned that so-called additive techniques would usurp incumbent manufacturing processes, today they are increasingly seen as complementary: another tool in the toolbox.

But according to Prof Richard Hague, director of the EPSRC centre for additive manufacturing, fundamental breakthroughs are on the horizon that could ultimately help realise some of the more exotic predictions that have been made for the technology.

Prof Richard Hague, Director, EPSRC Centre for additive manufacturing

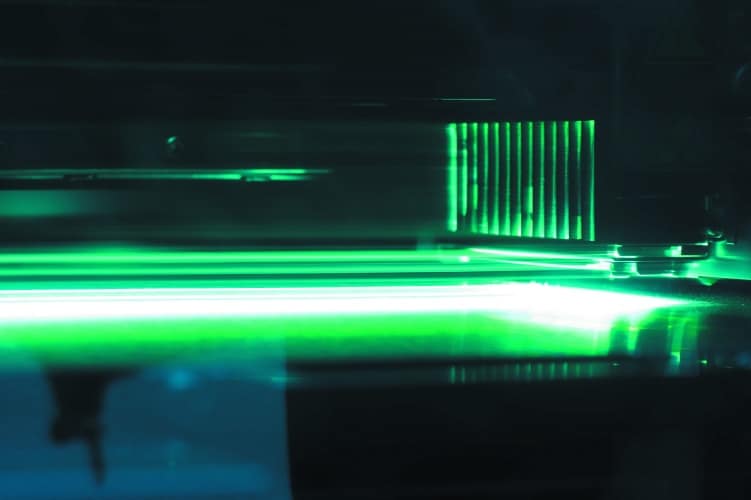

Based at Nottingham University, Hague’s 70-strong team of researchers is making something of a name for itself in one of additive’s most exciting vanguards: the field of multifunctional 3D printing, or 4D printing as it’s sometimes called.

While existing systems typically use just one material, the idea is that multifunctional printers will produce fully functional components from multiple materials, both metals and plastics. It sounds fanciful, but the group has already made significant progress and such techniques could, it is believed, one day enable manufacturers to print entire electronic devices – such as mobile phones – in one go.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of premium content. Register for free to unlock unlimited access to all of our premium content, as well as the latest technology news, industry opinion and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

National Gas receives funding to develop Gravitricity underground hydrogen storage system

One single rock salt mine - Winsford - has 23 <i>MILLION </i>cubic metres of void and even allowing for 10% of that void set aside for hazardous waste...