Western society is currently experiencing a crisis of conscience versus convenience. The boom in online shopping, food delivery platforms and new mobility providers has made it easier than ever to get what we want and where we want, around the clock. This ultra-convenient consumerism comes at a cost, however, and the streets of our cities are clogging like arteries exposed to a few too many takeaway pizzas.

Autonomous delivery systems of different stripes are emerging to help solve this logistical conundrum, from underground hyperloops for distance freight, to robotic drones that service the all-important last mile. Starship Technologies falls under the latter category, its six-wheeled robots delivering groceries, hot food and packages to customers on demand. When The Engineer first spoke with the company back in 2016, its bots had covered just 5,000 miles in testing. Four years later, things have moved on quite a bit.

“We’re over 350,000 miles travelled now,” said Henry Harris-Burland, VP of marketing at Starship.

“One of the biggest differences is that we weren’t a commercial service back then. We were probably doing testing, we may have been doing one or two deliveries for a couple of partners, but it’s a complete transformation. We’ve done over 100,000 autonomous deliveries now, 5 million road crossings. We’re doing something like 10-15,000 road crossings every day with our robots.”

Starship’s robots travel at around 4mph on paths and across roads, sharing the space with - and giving way to - pedestrians. They use a combination of machine vision and GPS to navigate, building up a richer picture of their environment over time. Appearance wise, the robots haven’t changed much since when they were testing in Lewisham four years ago, but there have been incremental upgrades in the hardware, as well as major software and battery advances.

“We do have new cameras,” said Harris-Burland. “There’s 10 cameras instead of eight cameras now. There’s all sorts of sensor fusion that we didn’t have previously.

“The batteries have changed as well. Previously we had batteries that were running maybe three hours. Now we’ve got batteries that last all day, 18 hours or more.”

On a particularly busy day, the delivery bots can cover up to 50 miles on a single charge. It’s this improvement, combined with the leaps in autonomy, that has underpinned Starship’s rapid commercial expansion.

“That’s where the improvements have come, in the autonomous driving, in the machine learning,” said Harris-Burland. “In our understanding of ‘Is that a trash can? Is it a bicycle? Is it a pedestrian?’”

Four years ago, the company was partnering with food platforms like Just Eat. Today, it operates its own platform that third parties sign up to. For example, in Milton Keynes you can go on to the Starship app and order groceries from Tesco or Co-op, or food from Frankie & Benny’s. When the robot arrives to the designated drop-off around 30 minutes later, the customer uses the app to unlock the lid and retrieve the order.

“We’re talking about hundreds of deliveries a day in Milton Keynes,” Harris-Burland explained. “Thousands and thousands of customers. Something like more than 75 per cent of the entire area that we operate in has had a robot delivery.”

Though Milton Keynes has been a major neighbourhood success, the biggest market is the US, where Starship robots can be found across eight university campuses and one corporate campus. The company is also operating on industrial campuses in Germany and Denmark, as well as a neighbourhood in Tallinn, Estonia. In all these locations, says Harris-Burland, social acceptance comes easy once the initial novelty wears off.

“It’s just commonplace in the areas that we operate in,” he said. “They’re seen every day, out in the public, on the sidewalks on pavements, and they’ve been embraced universally, which is one of the most important things for us.”

It’s perhaps an indictment of human nature that one of the first questions people ask is how often the bots get stolen or vandalised. On college campuses in particular, one might envision the diminutive bots on the receiving end of some varsity hijinks.

“We have had incidents,” Harris-Burland admitted. “But we feel comfortable with where we’re at right now, because no one has managed to steal one or anything like that. There’s alarms if you pick it up. As soon as you pick it up it’s like a screeching car alarm going off.”

Part of the company’s sell has been the potential impact on congestion and pollution. Not every robot delivery is necessarily replacing a car journey, but Starship’s neighbourhood operations in particular can alleviate the need to jump in the car for that pint of milk or those emergency baby wipes. Autonomous delivery could help cut car journeys as well as reduce the number of delivery vans servicing the last mile. When it comes to moving bigger quantities of goods over greater distances, however, 4mph robots aren’t a good fit.

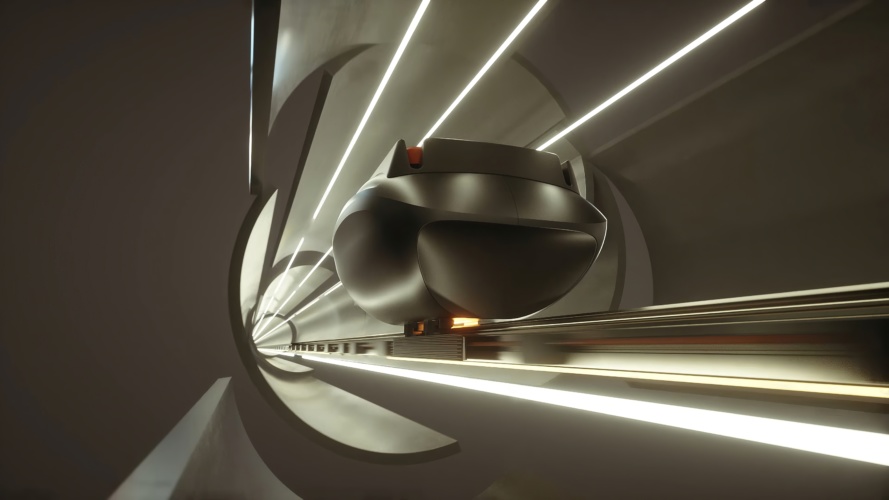

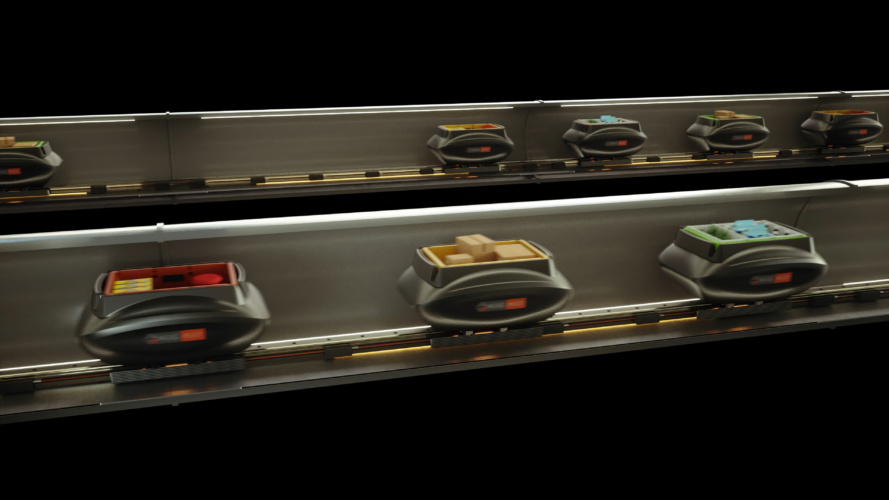

Magway is a UK company hoping to fill that middle ground. Inspired by Hyperloop, it plans to use linear motors to propel crates - or totes - of goods on a nationwide network of pipes, reducing HGV freight traffic. It recently raised over £1.5m through crowdfunding, more than doubling its original target. According to co-founder and technical director Rupert Cruise, the concept has struck a particular chord with younger people.

“53 per cent of our investors are under 30,” he told The Engineer. “So we’re definitely speaking to the younger generation. And just over 70 per cent are under 40.

“We also won a £1.9m government grant in December, which kicks off on the first of March. Those two pots of money give us a runway basically for the next two years.”

Unlike Hyperloop, Magway’s technology doesn’t require a vacuum, propelling its freight at a relatively sedate 54 km/h. Precision control of the linear motors allows totes to travel just fractions of seconds apart. This gives the network extremely high carrying capacity, even with the relatively low speeds.

“We’ve got phenomenal results from our demonstrator,” Cruise explained. “We’ve only got a short section of track within our test facility. The total length of the track is only 12 metres. We’re able to accelerate the system up to 8m/s safely, and have it running in both directions. The rate of acceleration – though we wouldn’t ever do this on the full-scale system – is equivalent to a high-performance motorbike.”

The recently secured funds will help finance a 1km development loop, with prospective sites being explored at the Olympic Park as well as the MTC in Coventry. Beyond that, the company has plans for a commercial pilot and is seeking to partner with an airport, where logistics operations are often highly time sensitive and high value. An airport pilot would probably not require much, if any tunnelling. If Magway is to take its solution nationwide, however, some major digging is likely to be required.

“One option is to run pipes along the surface, and that’s clearly the cheapest option,” said Pierce. “But all of our costing has been done around what we call shallow build systems, which is a cut and cover system. The pipes would come with the track pre-inserted, in 12 metre sections. They connect together and we would sling all of that a kilometre at a time into the trench.”

According to Cruise, there are also a number of promising pipe technologies emerging that could dramatically speed rollout. In Australia, a company called Long Pipes Ltd is essentially printing pipes in a fabric-type material, which is then inflated and cured using resin to produce a continuous length of pipe with no joins, and no need for welders. It’s in the early stages of development, but the technology could someday be adapted for the type of large-scale rollout that a Magway network would require.

“We can lay about 200m per day of pipe,” said Cruise. “Long Pipes, depending on the terrain, can lay between 2-6km per day. It’s phenomenal technology.”

Where deeper sections are required, Magway will look to established tunnel boring techniques, combined with automatic track laying. These methods will mean the tunnels will only be accessible at either end, raising the inevitable question of what happens when something goes wrong. It’s a question Cruise hears frequently. He understands the concerns but says the system will be designed with both resiliency and redundancy.

“Step one is we always have two pipes,” he explained. “Step two is that we will always interconnect those pipes every kilometre, so if there is an (outbound) blockage, the outbound traffic can be rerouted. Vehicles can also travel both ways in the pipe. So if there’s a blockage we can actually reverse out and vacate the pipe.”

Robotic vehicles will also be used to sort blockages. Where robots can’t solve a problem, sections of pipe can be dug up for repairs to take place. But if the system works as planned, that type of intervention will be extremely rare. The linear motors, in particular, are built to last.

“Our manufacturing partner supplied linear motors to Disney 30 years ago, and they’ve never had a spare,” Cruise said. “One of their motors has been underwater for 20 years, never had a spare. That’s how resilient they are.

“The wear element is the wheels, but they go in and out of the pipe, so we can always replace them every few years. Whereas the tracks, we don’t want to wear, because everything we put in the ground, we don’t want to see again for another 40 or 50 years.”

For a Magway network to be effective, it will have to integrate with major retailers and distributors like Amazon and Ocado, both of which are already fully embracing the frontiers of automation. Indeed, Ocado was a partner with Magway for one of its earlier Innovate UK grants and retains an interest in the company. According to CTO Paul Clarke, Ocado’s trunk and last mile deliveries are simply important pieces in a larger logistics puzzle. “Nothing for us in the last mile would work if we didn’t have that amazing precision upstream,” he told The Engineer.

As an online-only operation, Ocado relies on the doorstep interaction more than any other supermarket. This of course raises the question whether autonomous deliveries would ever be desirable for a company that places such emphasis on that point of contact.

“A typical Ocado order is 50 items and customers really value us bringing that into their home,” said Clarke. “That’s a premium service, in that it sets the bar high for others in terms of what last mile delivery means…getting to the curb is important, but we want to be able to get from the kerb to the kitchen table.”

How Ocado is reshaping retail with robotics

Magnetic freight delivery concept could cut congestion

In its relentless pursuit of optimisation, Ocado has always turned to data, from route efficiency and van speeds to warehouse forecasting and robotic picking. But when it comes to autonomous delivery, data is hard to come by, with high stakes and heavy regulation inhibiting the scale of testing one might desire. Simulation has a role to play, says Clarke, but sooner or later you have to get your feet wet.

“There’s a tendency for people to stand around swimming pools trying to learn how to swim the Atlantic,” he said. “We’re going to have to find other ways to learn.”

One of the ways being looked at by the company is a ‘living labs’ model, whereby day-to-day operations coincide with a type of real-life beta testing.

“For example, our first-generation warehouse in Hatfield has been a living lab,” Clarke explained. “It’s shipped millions of customer orders over the years, but it’s done that while we’ve ruthlessly continued to invent new mousetraps, new ways of doing what

we do.”

A new project will replicate this model on a much wider scale, first on a business park, then countywide across Hertfordshire. It will look at the intersection of autonomous vehicles, drones, robots, smart infrastructure and smart services. A consortium led by Ocado will start off on semi-familiar territory, moving groceries autonomously, but will also look to move people.

“We eventually want to take that off the park and out to a county level, turning Hertfordshire into a smart county,” Clarke explained.

The ultimate plan is for the project to become a steppingstone towards smart cities, where Ocado and its partners can learn on the job and scale up as they go.

“It’s not some sort of theoretical set-up,” said Clarke. “On that park we have a hospital, Ocado head office, the first Ocado warehouse, a University of Hertfordshire engineering hub, residential property, a school. And that creates a rich ecosystem for this experimentation.”

Last year the company launched Ocado Zoom, a rapid grocery delivery service based around its Acton warehouse in West London. It offers customers a choice of more than 10,000 items, delivered in under 60 minutes.

“Typically, it’s actually below half an hour even 20 minutes,” said Clarke.

Further down the line, Ocado Zoom could be co-located with vertical farms and industrial kitchens, getting ultra-fresh produce and cooked meals to customers in record time. Coupled with a green logistics infrastructure, it’s a system that could deliver on both conscience and convenience.

“Now you have the potential to go from plant to kitchen table in maybe two hours,” said Clarke. “And that is freshness that, unless you live on a farm, you will never experience. That’s a properly interesting, integrated food machine, from growing to last mile logistics.”

Poll: Should the UK’s railways be renationalised?

I think that a network inclusive of the vehicles on it would make sense. However it remains to be seen if there is any plan for it to be for the...