Layers of manufacturing

The Warwick Manufacturing Group is set to use a bespoke machine for investigating methods of creating lightweight components. Jason Ford reports

Britain’s manufacturers will soon have access to a tool that is likely to take lightweight research to new levels.

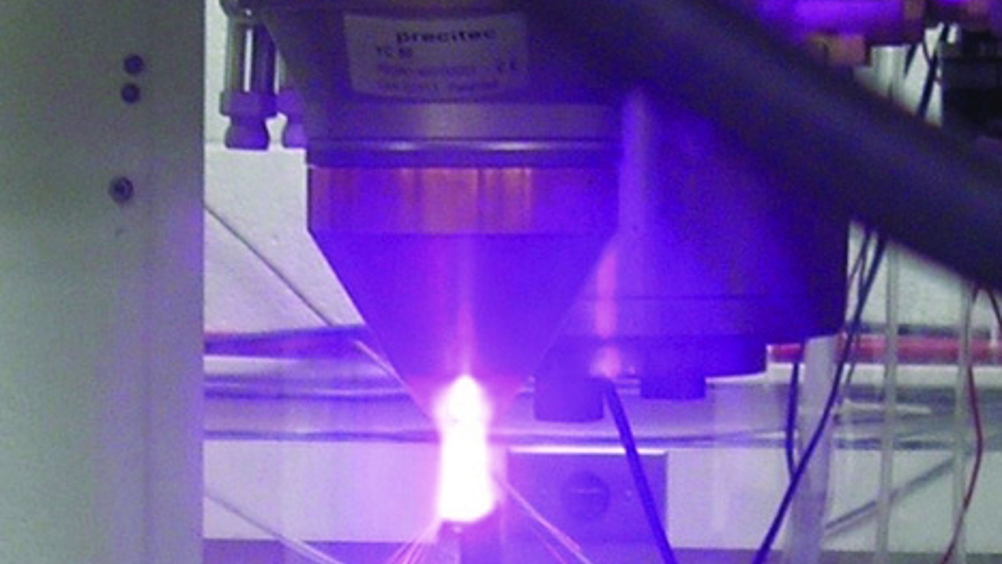

Unique to Warwick Manufacturing Group (WMG), the bespoke machine will let the West Midlands team investigate whether plasma transfer arc (PTA) welding and additive manufacturing (AM) can be used to manufacture light-weight 3D components.

Put simply, AM builds parts gradually through the deposition and heating of layers of metal powder and WMG’s machine, delivered on 9 March 2012, is expected to provide fresh insights into exploiting the process.

The machine, described as a ‘hybrid additive subtractive manufacturing system’, will be employed for lightweighting research, for investigating the direct, tool-less manufacture of parts for sectors, including automotive, autosports and medical.

The finished parts created by Warwick’s latest research tool may represent a paradigm shift in Britain’s manufacturing capability, but the machine itself is essentially a CNC device. Dr Gregory Gibbons, a senior research fellow at WMG, told The Engineer that the PTA torch can be simultaneously fed from a powder or a wire feed, making it highly flexible.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of premium content. Register for free to unlock unlimited access to all of our premium content, as well as the latest technology news, industry opinion and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...