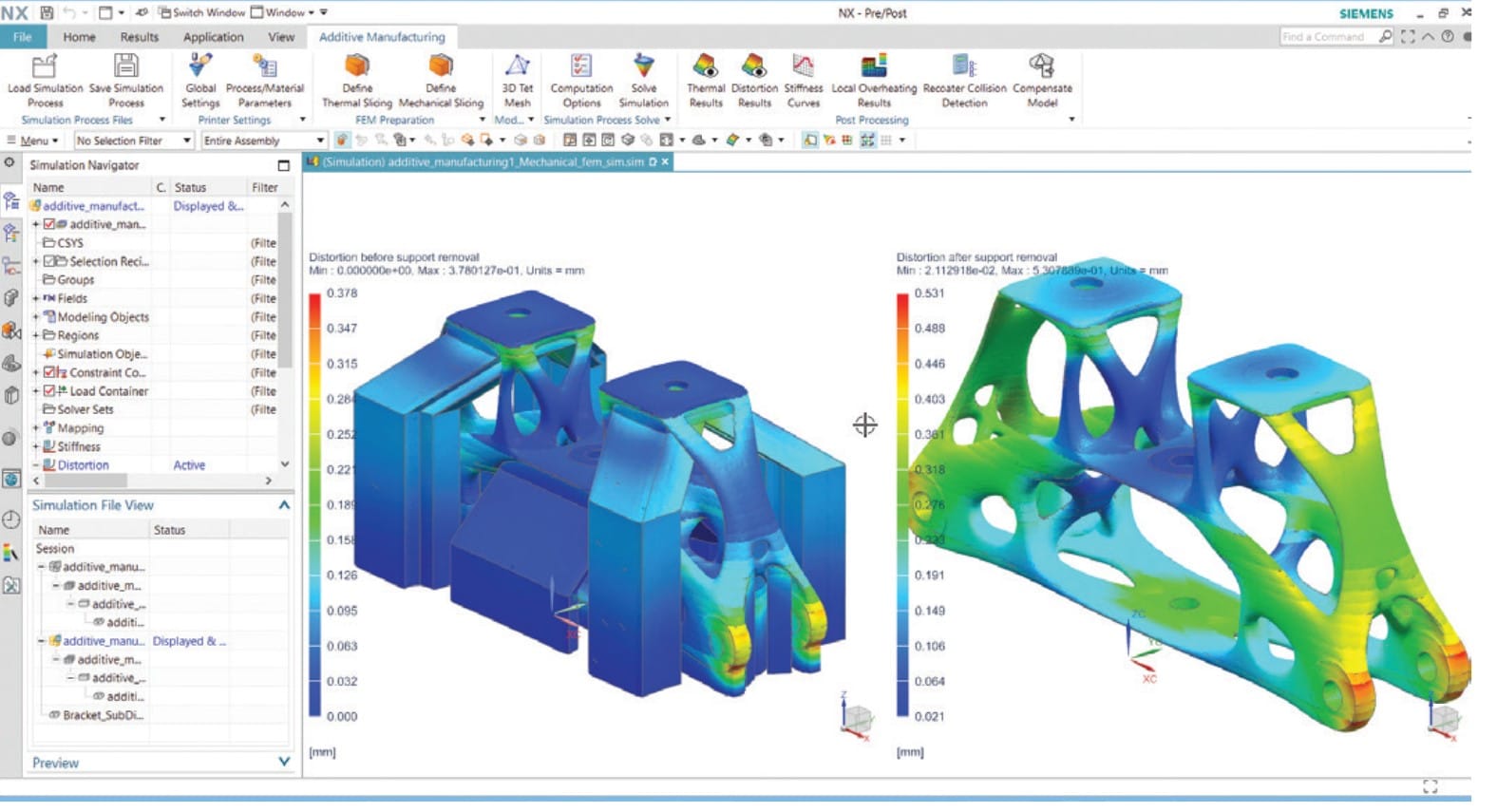

Using simulation to predict additive outcomes

Ahead of the 2019 Additive International summit, speaker Michele Garibaldi of Siemens Digital Industries discusses the need for viable simulation technology to predict the performance of components built with specific AM processes.

Additive manufacturing processes such as laser powder bed fusion (LPBF) and Electron Beam Melting (EBM) deal with large scales of data. Components can have a build envelope of 30 cm, the material melt pool is only around 100 microns, while the laser needs to travel 10s of kilometres on its path to build a full part. Combined with cooling rates of 1 million degrees per second, a vast array of variables need to run seamlessly, quickly and leave little margin for error to create accurate and predictable components.

By their nature, additive processes like LPBF can create structures with more complex geometries, manipulating material properties to build them point by point. This means localised areas can vary within a single part. For example, the hardness or stiffness can vary throughout the microstructure, or pores can be included in certain regions of the part. Tailoring properties location by location in any given part can optimise the efficiency and performance of the components, but can be difficult to achieve – and produce consistently.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of premium content. Register for free to unlock unlimited access to all of our premium content, as well as the latest technology news, industry opinion and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...