More in

3D jet writer creates the right environment to understand spread of cancer

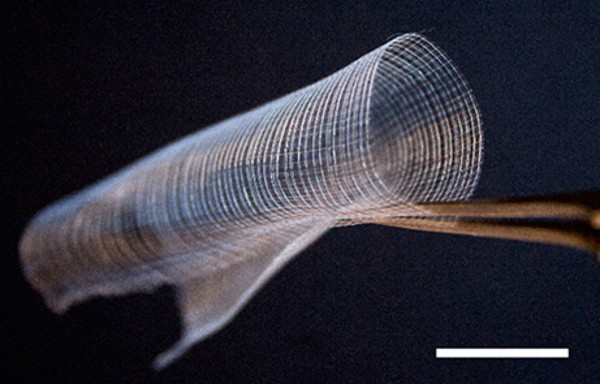

A 3D jet writer has been used to create a lifelike cancer environment out of polymer, an advance that could help to provide insights into how the disease spreads.

Research has shown that most cancer deaths happen because of how it spreads – or metastasises - in the body. A drawback for cancer treatment is not being able to experiment with metastasis and eliminate what causes it to spread.

Previous studies have used a 3D printer to recreate a controlled cancer environment, but these replicas are still not realistic enough for drug screening.

“We need a much finer resolution than what a 3D printer can create,” said Luis Solorio, an assistant professor of biomedical engineering at Purdue University in Indiana who worked on the project with researchers from the University of Michigan.

The team of researchers - led by Dr Jacob H. Jordahl in the lab of Prof Joerg Lahann at the University of Michigan - have proposed 3D writing instead of printing. The 3D jet writer acts like a 3D printer by producing polymer microtissues as they are shaped in the body, but on a smaller, more authentic scale with pore sizes large enough for cells to enter the polymer structure.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...