3D-printed structures change shape and colour

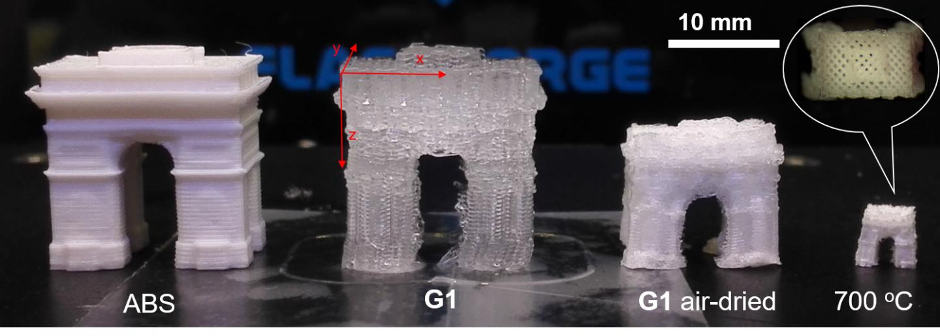

Researchers have developed a smart ink that turns 3D-printed structures into objects that can change shape and colour.

The innovation from Dartmouth College, New Hampshire promises to add more functionality to 3D printing and could pave the way to a new generation of printed material.

The advance in form-changing intelligent printing - or 4D printing – is claimed to provide a low-cost alternative to printing precision parts.

"This technique gives life to 3D-printed objects," said Chenfeng Ke, an assistant professor of chemistry at Dartmouth. "While many 3D-printed structures are just shapes that don't reflect the molecular properties of the material, these inks bring functional molecules to the 3D printing world. We can now print smart objects for a variety of uses."

Many 3D printing protocols rely on photo-curing resins and result in hard plastic objects with rigid, but random molecular architectures. According to Dartmouth, the new process allows designers to retain specific molecular alignments and functions in a material and converts those structures for use in 3D printing.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...