Braiding technique enables antennae fabrication for next-gen devices

Antennae that work at frequencies needed for next generation phones and wireless devices can be fabricated with a machine developed in the US.

These devices will require antennae that work at tens of gigahertz but making them will require braided filaments of about one micrometre in diameter.

Now a team of researchers from the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) has developed a simple machine that uses the surface tension of water to grab and manipulate microscopic objects, offering a potentially powerful tool for nanoscopic manufacturing. The research is published in Nature.

“Our work offers a potentially inexpensive way to manufacture microstructured and possibly nanostructured materials,” said Vinothan Manoharan, the Wagner Family Professor of Chemical Engineering and Professor of Physics at SEAS and senior author of the paper. “Unlike other micromanipulation methods, like laser tweezers, our machines can be made easily. We use a tank of water and a 3D printer, like the ones found at many public libraries.”

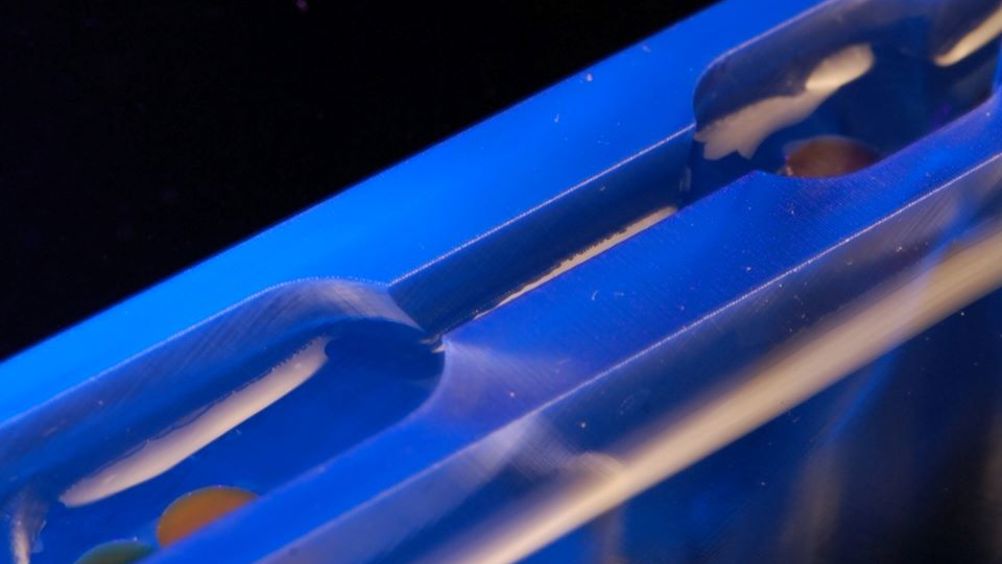

The machine is a 3D-printed plastic rectangle and its interior is carved with channels that intersect. Each channel – with hydrophilic walls - has wide and narrow sections.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

INWED Engineering Profile: Naval Architect Ellie Driver

Not a woman I´d want to cross … oh, that was Elle Driver