Digital technologies automate placement of cars in shipping containers

More cars could be shipped in fewer containers thanks to software developed at WMG for Trans-Rak International.

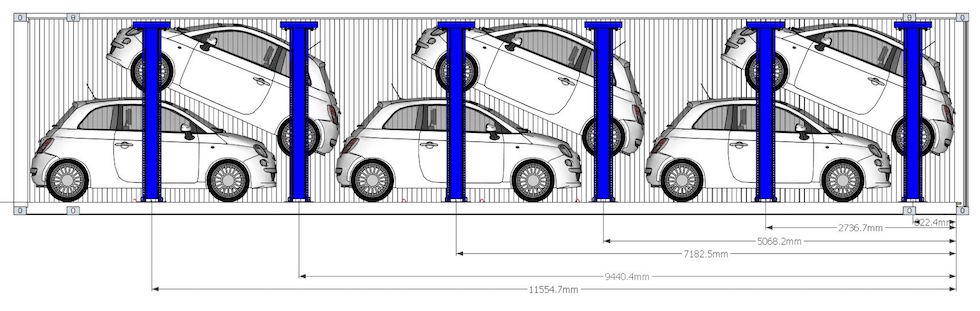

Working with Warwickshire-based manufacturer Trans-Rak International (TRI), Piero Filippin, innovation manager at WMG at the University of Warwick, has created a system that automates the placement of cars in a shipping container, allowing for any combination of make or model.

The software operates a car racking system produced by TRI, and the combined technologies could lead to savings for the global automotive industry, enabling more cars to fit into fewer containers, as they are transported across the world.

Currently, an average of two cars can be stored in each container but that capacity would be doubled using the new system.

The software generates recommendations on any number of cars, of different makes and models, to be stored in the most efficient possible combination and position.

Users select the number of cars, as well as which makes/models, they wish to transport. A numerical process simulates numerous loading scenarios, and generates a report of the most efficient combination of cars in each container, plus their exact positioning.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

CCC Report Finds UK Climate Targets Still Within Reach

In 1990 67% of the UK´s electricity came from coal-fired power stations and even without renewables the transition to gas was a major contributor to...