New technique developed to transform waste CO2 into high-value chemicals

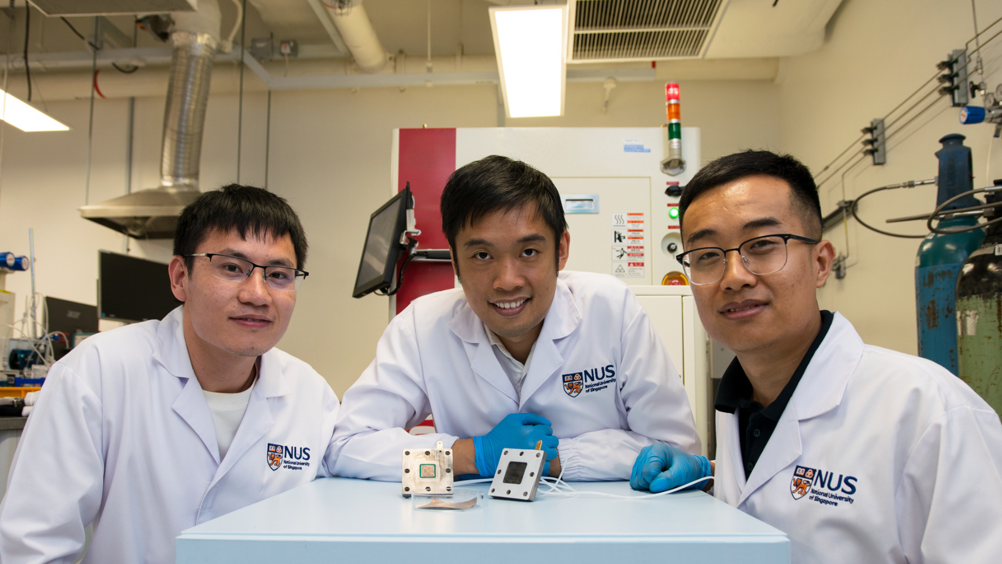

Researchers from the National University of Singapore (NUS) have developed a technique that could advance the conversion of waste CO2 into value-added chemicals and fuels.

According to the NUS researchers, their new technique has enabled the direct conversion of CO2 from treated flue gas, a common by-product of industrial processes, into high-value multi-carbon (C2+) products.

Specifically, these C2+ products, such as ethylene and ethanol, are essential raw materials to produce everyday compounds such as plastics, polymers and detergents.

The researchers said that this advance could not only circumvent the need for high-purity CO2 but also repurpose a prevalent waste product, working towards closing the carbon cycle and reducing reliance on fossil fuels.

Traditionally, the process of transforming CO2 into a range of feedstocks for chemicals and fuels demands high purity-CO2, energy-intensive purification and high costs, according to the researchers.

The presence of oxygen impurities in flue gas often results in undesired side reactions, which can significantly reduce the efficiency of the CO2 reduction process.

The research team, led by Assistant Professor Yanwei Lum from the Department of Chemical and Biomolecular Engineering, the NUS College of Design and Engineering, aimed to avoid these challenges by integrating catalyst design with electrolyte selection.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

UK Enters ‘Golden Age of Nuclear’

Apologies if this is a duplicate post - a glitch appears to have removed the first one: > While I welcome the announcement of this project, I note...