The group, from the university’s Department of Materials Science and Engineering has applied the technique - known as cold sintering - to produce bioactive glasses which could be used to repair human tissues in a safe, sustainable way.

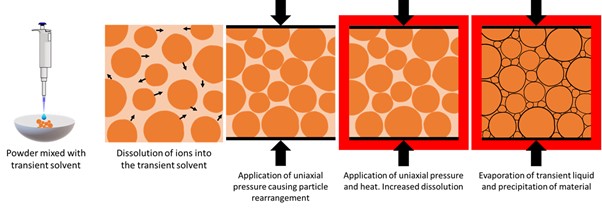

The process has been used to produce glass components with a density of 95 per cent from powders by applying pressure and heat up to 250°C in the presence of simple solvents such as water. Existing methods require temperatures of at least 1000°C.

The idea for the process development came from an understanding of the cold sintering of ceramics. In addition to densifying (forming a dense final product from powder by applying heat and pressure) a range of specialist glasses, cold sintering is of particular interest for bioactive glasses such as Bioglass, which are used to promote bone growth or to create scaffold structures which, when placed in the body, can contribute to the rapid repair of damaged tissue.

According to the group, using the process to densify Bioglass brings a number of advantages.

Firstly, the low temperatures mean that glasses can be co-densified with polymers to achieve better mechanical properties. The team also envisages the potential for drugs to be embedded in the Bioglass before densification to create a slow release delivery system.

What’s more, cold sintered glasses can be used to coat surfaces and stick together a wide range of materials, including other glasses, ceramics, composites and metals. The team claims that the scope to create a range of composites with high polymer to high glass volume fractions could enable a wide range of bio-applications

Commenting on the research, project lead and materials Science and Engineering PhD student, Jess Andrews said: “Cold sintering is still a relatively new technique, but we are beginning to see its huge potential - it has already been utilised in a really broad range of applications from electroceramics to bioactive glasses. I think it will be exciting to see what larger scale changes can come from these initial developments in the lab.”

Water-filled glass promises to improve building design

Additive manufacturing of glass optics

The technique's potential has been recognised by Johnson Matthey, which has sponsored the research and already applied for a patent for the process. A paper on the work appears in the Johnson Matthey Technology Review.

Jonathan Booth, Research Manager at Johnson Matthey Technology Centre, said: “We are very excited about the enabling potential of this technology which will hopefully allow us to explore new functional glass, polymer composites hitherto impossible to manufacture.”

Construction industry lags in tech adoption

Are these the best people to ask "Insights from 2,000 Industry Leaders"? - what would their customers views be like (perhaps more...