Siemens outline benefits and requirements for the digital factory

There probably isn’t much you can teach Siemens about manufacturing, a company that has been in the UK for 170 years and currently employs around 15,000 staff at 14 sites around the country.

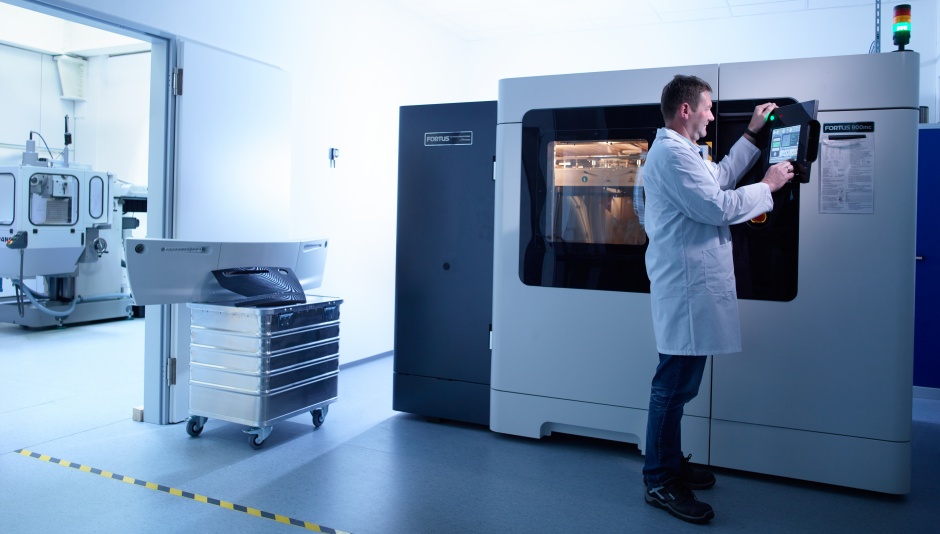

The company remains committed to the UK as recent investments - £200m into a rail manufacturing facility, and £27m toward a new 3D printing factory – show.

Despite its size and reach, Siemens is no different to any other manufacturer that has seen – and seized – the opportunities brought about through Industry 4.0 and the digitalisation technologies that have made it happen.

In his ‘New skills for the Digital Era’ presentation at MACH 2018, Alan Norbury, Siemens Industrial CTO, gave delegates an insight into how they can embrace – or improve upon - Ind 4.0 and the skills challenges that lay ahead inside the digital factory.

For the majority of manufacturers, Ind 4.0 will be implemented as a series of modifications to plant and processes. Turning standalone items of machinery into IoT devices is relatively straightforward if those pieces of machinery have a suitable port that connects them to the internet.

Register now to continue reading

Thanks for visiting The Engineer. You’ve now reached your monthly limit of news stories. Register for free to unlock unlimited access to all of our news coverage, as well as premium content including opinion, in-depth features and special reports.

Benefits of registering

-

In-depth insights and coverage of key emerging trends

-

Unrestricted access to special reports throughout the year

-

Daily technology news delivered straight to your inbox

INWED Engineering Profile: Naval Architect Ellie Driver

Not a woman I´d want to cross … oh, that was Elle Driver