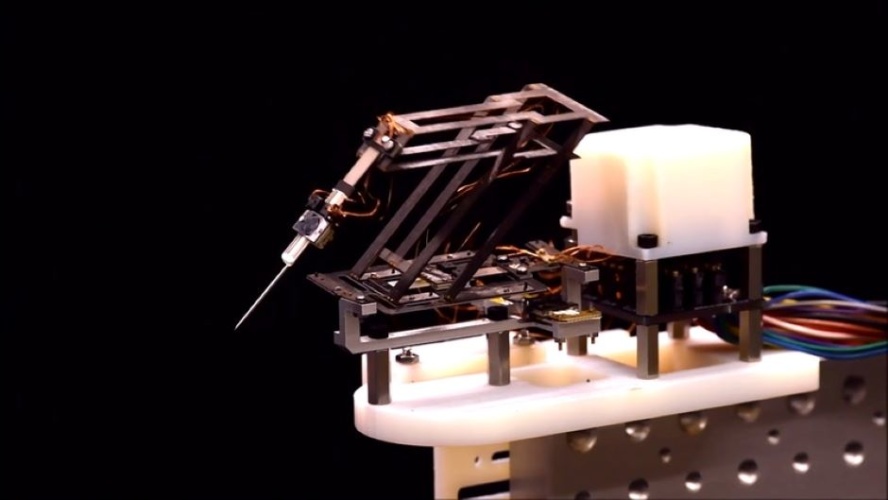

The mini-RCM is the result of a collaboration between Robert Wood, Ph.D. from the Wyss Institute for Biologically Inspired Engineering at Harvard University, and Robotics Engineer Hiroyuki Suzuki of Sony Corporation.

Microfabricated milliDelta robot set for role in manufacturing and medicine

Tiny origami robot unfolds in stomach

How the Versius robot could bring keyhole surgery to the masses

"The Wood lab's unique technical capabilities for making micro-robots have led to a number of impressive inventions over the last few years, and I was convinced that it also had the potential to make a breakthrough in the field of medical manipulators as well," Suzuki said in a statement. "This project has been a great success."

The lightweight robot is the size of a tennis ball and successfully performed mock surgical tasks, which are described in Nature Machine Intelligence.

To create their miniature surgical robot, Suzuki and Wood used the Pop-Up MEMS manufacturing technique developed in Wood's lab, in which materials are deposited on top of each other in layers that are bonded together, then laser-cut in a specific pattern that allows the desired three-dimensional shape to "pop up".

The team created a parallelogram shape to serve as the main structure of the robot, then fabricated three linear actuators (mini-LAs) to control the robot's movement: one parallel to the bottom of the parallelogram that raises and lowers it, one perpendicular to the parallelogram that rotates it, and one at the tip of the parallelogram that extends and retracts the tool in use.

The mini-LAs are built around a piezoelectric ceramic material that changes shape when an electrical field is applied. The shape change pushes the mini-LA's ‘runner unit’ along its ‘rail unit’, and that linear motion moves the robot. The team also integrated LED-based optical sensors into the mini-LA to detect and correct any deviations from the desired movement.

To mimic the conditions of a teleoperated surgery, the team connected the mini-RCM to a Phantom Omni device, which manipulated the mini-RCM in response to the movements of a user's hand controlling a pen-like tool. Their first test evaluated a human's ability to trace a tiny square smaller than the tip of a ballpoint pen, looking through a microscope and either tracing it by hand, or tracing it using the mini-RCM. The mini-RCM tests are said to have reduced error by 68% compared to manual operation.

The researchers then created a mock version of a retinal vein cannulation, a procedure in which a surgeon inserts a needle through the eye to inject therapeutics into the veins at the back of the eyeball. They fabricated a silicone tube the same size as the retinal vein and punctured it with a needle attached to the end of the mini-RCM without causing local damage or disruption.

"The Pop-Up MEMS method is proving to be a valuable approach in a number of areas that require small yet sophisticated machines, and it was very satisfying to know that it has the potential to improve the safety and efficiency of surgeries to make them even less invasive for patients," said Wood.

The researchers aim to increase the force of the robot's actuators to cover the maximum forces experienced during an operation, and improve its positioning precision. They are also investigating using a laser with a shorter pulse during the machining process to improve the mini-LAs' sensing resolution.

Poll: Should the UK’s railways be renationalised?

I think the rail infrastructure should remain "nationalised" in the same way that the roads and motorways are "nationalised". I think the trains that...