Adaptive Multi-Chem technology brings together the company’s knowledge from a variety of projects, including four seasons as the sole battery supplier to FIA Formula E.

Usually manufacturers are faced with a compromise between energy density and power density as they try to minimise the size and weight of battery packs for a target performance level.

£55m funding for UK battery research

Hyperdrive opens UK's largest independent battery research facility

Williams and Unipart form new EV battery manufacturer

Cells designed for optimum storage capacity have a different physical form from high power cells and are not suited to the sudden large current draws needed for high power. Cells are usually optimised for either energy storage or power.

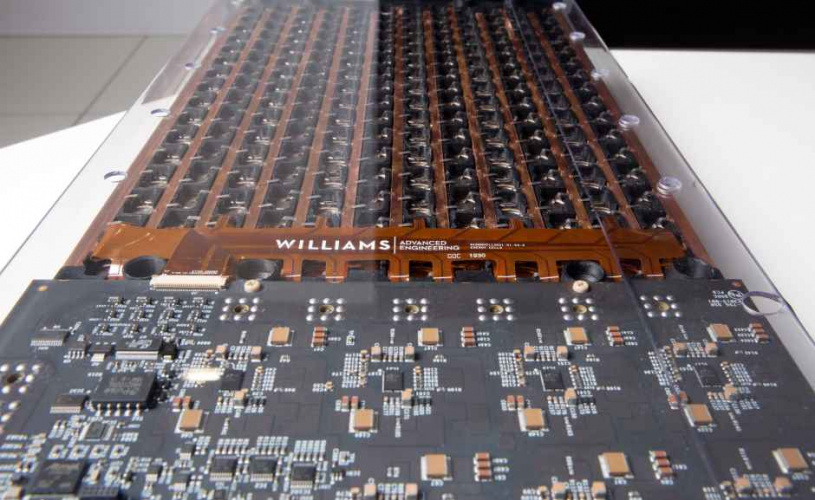

Williams’ solution with Adaptive Multi-Chem technology is to integrate both high energy and high power cells in a single power pack. A state-of-the-art bi-directional DC/DC converter links the two and also contains software to manage the transfer of current between them. The company claims the technology allows a 37% increase in energy density for a target power density. “Because high power is only needed in short bursts, the overall package can be kept small,” said Williams Advanced Engineering technical director Paul McNamara.

The system is modular, allowing the proportion of energy and power cells to be varied so that the peak power, continuous power and stored energy of the unit can be tailored to customers’ requirements. A compact thermal management system provides cooling without unnecessary bulk.

The unit shown at Cenex had a total stored energy of 60kWh, with a core battery mass of 345kg. Peak deployment power was 550kW (in a 20 second pulse).

It also showcased an exoskeleton manufactured using the company’s lightweighting technology, 223TM. This uses a unique production process which enables the creation of 3D structures from a two-dimensional composite material. The complete base and case for the battery weighed only 40kg.

Poll: Should the UK’s railways be renationalised?

I think that a network inclusive of the vehicles on it would make sense. However it remains to be seen if there is any plan for it to be for the...