In its recently updated Net Zero Roadmap, the International Energy Agency (IEA) concludes that a pathway to limiting global warming to 1.5 °C by 2030 is very challenging – but remains open. The good news is that 80% of the required reduction in emissions can come from known sources that are available today, like improving energy efficiency. This is where energy efficient motor technology is critical, both for industrial productivity and for decarbonization initiatives to reduce the CO2 emissions related to generating electricity.

There is a huge opportunity for energy savings since motors in equipment such as pumps, fans and compressors use around two-thirds of the electricity consumed by industry. In fact, simply replacing the 300 million-plus electric motor-driven systems operating today with optimized, high-efficiency versions would cut worldwide electricity consumption by up to 10%.

Governments worldwide have acted on this realization by introducing increasingly stringent efficiency regulations for motors. A good example is the EU’s Ecodesign Directive, which since July 2023 has demanded IE4 “Super-premium” energy efficiency for many common types of motor technologies in the range of 75 – 200 kW. Other countries and regions are following this lead.

While acknowledging that actively supporting the IE4 standard is a critical step, we can still go much further with current technology. ABB has been always an advocate for productivity and a pioneer of energy efficiency. That is why, five years ago, we launched our “Ultra-premium” energy efficiency IE5 SynRM motors. Now we have taken the next step by launching Hyper-efficient IE6 motors based on the same well proven technology.

What does IE6 really mean?

Currently, there is no official standard that defines an efficiency class beyond IE5. Therefore, we have embraced the “20% principle”, because, so far, each progression in IE efficiency class has called for 20% lower energy losses than the one before. So, the design principle and ambition was for our own IE6 Hyper-efficiency motors to offer 20% lower losses than IE5.

The attraction of magnet-free SynRM technology

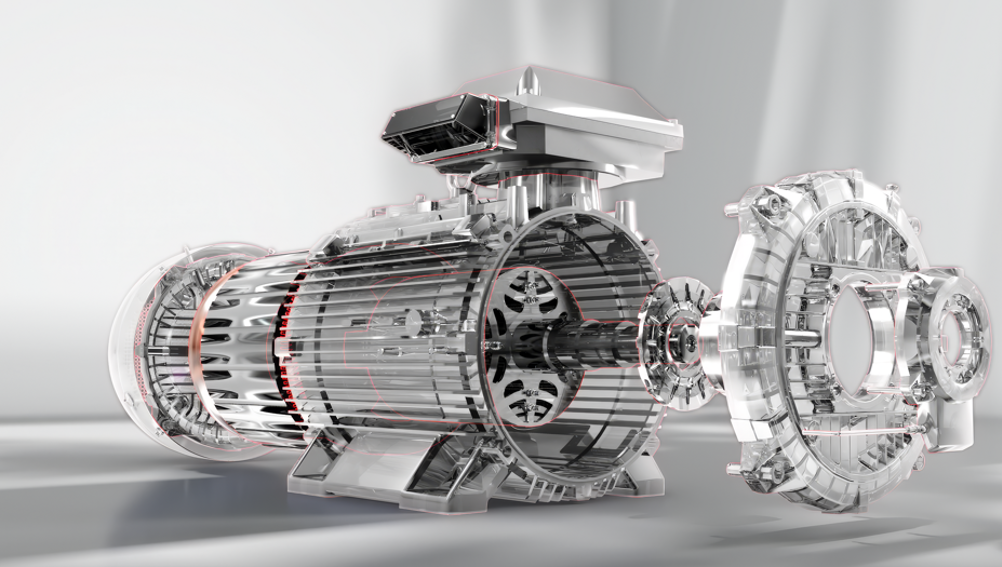

The breakthrough is not just about reaching IE6. We had already done that with other motor technologies in the ABB portfolio, such as permanent magnet (PM) and hybrid magnet-assisted SynRM (PMaSynRM). The world-first is that IE6 is now available through SynRM technology that combines the performance of a PM motor with the simplicity and service-friendliness of an induction motor.

The rotor in a SynRM motor has neither magnets nor windings and suffers virtually no power losses. The design also requires no rare earth metals and offers a high level of usability due to the wide availability of suitable variable speed drives (VSDs) to provide the required control capabilities. The result is that IE6 Hyper-efficiency is now a cost-effective option for a wide range of applications and industrial sectors. Furthermore, our commitment to reaching Net-Zero is substantiated by the fact that our SynRM motors do not use magnets and are also part of the ABB EcoSolutions™ product portfolio that provides enhanced transparency about each product’s circularity value and environmental impact.

The benefits of upgrading from induction motors

Since an IE6 SynRM motor is the same size as an equivalent IE3 induction motor, together with a VSD it offers the ideal upgrade package, with the opportunity to achieve more than 50% lower energy losses across a wide range of applications. For a 55 kW motor application running under a typical operational regime of 6,500 hours a year at 75% power, the return on investment (ROI) would be rapid – potentially less than a year, depending on energy costs. And over a 25-year lifetime the cost savings in energy could be over Euro 44k combined with a total saving of 66 tonnes of CO2.

Upgrading just one motor to IE6 will therefore make a tangible difference. If we could get the world to upgrade to Hyper-efficiency then it would be well on the path to accelerating the global drive for increased energy efficiency and industrial decarbonization.

Water Sector Talent Exodus Could Cripple The Sector

One possible reform to the Asset Management Plan (AMP) system would be to stagger the five year cycle across the ten or so water businesses, so that...