For pharmaceutical companies, every step of the production line and every aspect of their processes needs to be approved by the regulator. Although this provides security, it also presents the challenge of how to incorporate changes into production. Flexibility is not part of this regulatory system. Therefore, the industry does not have the luxury of trial and error when ramping up production of COVID-19 vaccinations. They need to get it right the first time, get their products approved by the regulators and start mass-producing as soon as possible.

Pharmaceutical companies follow established “good manufacturing practices” (GMPs) and “good automated manufacturing practices” (GAMPs). These are standards mandated by the European Medicines Agency and the US Food and Drug Administration. The standard regulates the quality assurance of pharmaceutical products by prescribing production, quality assurance and documentation of medicine production. The quality inspection of employees, facilities and material is of particular significance. Every step of the production needs to be traceable and the quality verified to pass stringent guidelines.

Industrial automation opportunity

To get the new COVID-19 production lines going, sizeable investments in people, plants and machinery are currently being made. There is an opportunity here to introduce the latest innovations in industrial automation into the pharmaceutical supply chain and get it certified by the regulators. Where before plant managers may have been wary to stop production to introduce new technologies, because they had to wait for approval by the authorities, now is the time to re-examine operations.

More from The Engineer's Industrialising Innovation Week

No matter what the new production line looks like, it will have to go through rigorous testing, quality assurance documentation, verification and acceptance by the regulator. So, why not introduce innovations that will shape the future of how medicines are produced?

In the field of quality inspection, the next technological frontier is to design systems that incorporate machine vision (MV) technologies to automatically highlight defects or faulty products. Better still, we can look at improved ways of streamlining the means of presenting products to these MV systems, with complete control integration between both the motion and vision systems.

No automation without movement

It sounds self-evident but is often overlooked that automated processes require customised movements. At Beckhoff, we’ve developed an innovative motion control system that moves products in a completely frictionless manner. The technology is based on electromagnetic fields, on which planes levitate in freely programmable directions.

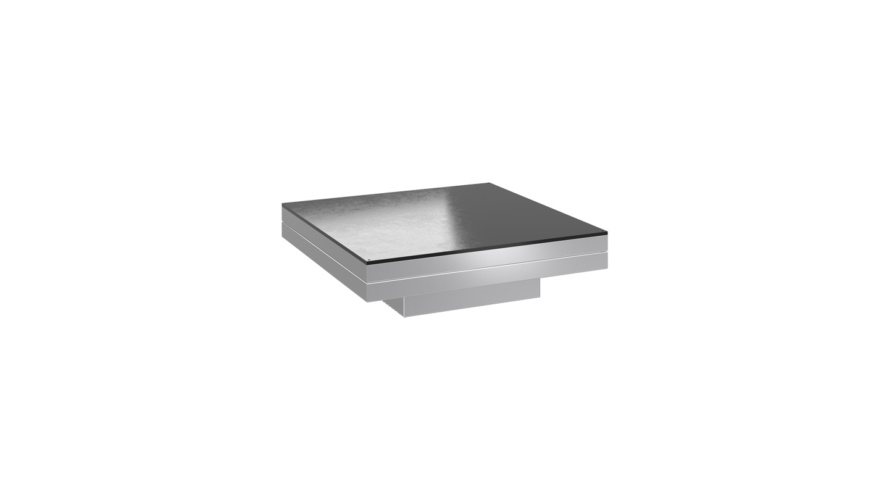

The system is called XPlanar and consists of three main components: the movers, the tiles that make up a floor for them and the Beckhoff TwinCAT3 automation software. The tiles can be arranged to fit any space requirements and the movers can be programmed to turn, wait, park or move in any direction. They have a stainless-steel surface as standard but can be fitted with containers to carry medicines, glasses or vials.

The principal advantage for the pharmaceutical industry is that the movers provide for a noiseless, frictionless and jerk-free movement. These characteristics are important when integrating a motion system with quality control automation. Since every mover is independent, it ensures that the contents of one mover do not come into contact with products on a different one, which opens up possibilities of combining products more flexibly, for instance during packaging.

The flexibility that this introduces to motion control means it is ideally suited for the quality assurance requirements of the pharmaceutical sector. Frictionless movement means that liquids don’t slosh over. The system can be flexibly reprogrammed to suit future challenges, which makes it the ideal motion system for the production, inspection and packaging of COVID-19 vaccines and any other medicines of the future.

Water Sector Talent Exodus Could Cripple The Sector

Well let´s do a little experiment. My last (10.4.25) half-yearly water/waste water bill from Severn Trent was £98.29. How much does not-for-profit Dŵr...