When selecting a pump to dose or meter fluids consistently into process, it goes without saying any pump selected must be accurate, and perform as expected over long periods with little or low maintenance.

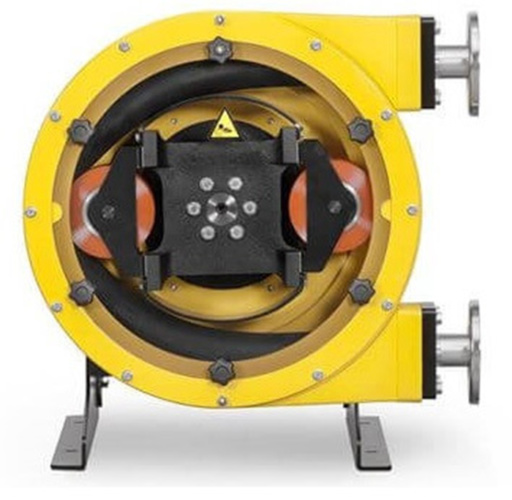

Whether it’s the transfer of flavourings into a recipe, chemicals for wastewater treatment or for the batching of hygienic liquids into packaging via a liquid filling machine - peristaltic Pumps are an excellent choice of pump to use in situations where flows are below 20,000L an hour, with pressures up to 16 bar.

Peristaltic Pumps excel in applications involving the handling liquids which may be viscous, abrasive, gaseous and volatile in nature and are typically used a wide range of fluids from Glues, Pastes, Sludges, Ink, and Food, to Chemicals, Cement and Slurries ranging in viscosity from 1 to 50,000cst.

But why are Peristaltic pump such a great choice for such applications and are there other considerations which should be explored prior to dosing or metering pump selection?

Below are 6 reasons why they excel in Dosing, Metering and low volume transfer applications:

Easy Clean & Low Maintenance

As peristaltic pumps are constructed with a single wearing part – the hose they are known to be very low maintenance.

However not only are they low maintenance but during batch or colour changes they can be cleaned effectively very easily, or have the internal hose changed and cleaned with little process stoppage. Peristaltic Pumps are up to 4 times quicker to clean & maintain than other positive displacement pump types.

When the hose does begin to show wear, it can be exchanged very simply, before being recycled or disposed of.

Non Clog, Hard Wearing & Run Dry

Peristaltic designs can accommodate solids as large as the internal diameter of the hose, and due to the movement do not clog. This makes them ideal for Sludges, Slurries, Pastes, Food, Cement, Sewage, and other applications which can contain large Solids, Stones, or unexpected objects.

Due to the absence of valves, Mechanical Seals, and O Rings the potential for clogging is removed as well as there being no opportunity for problematic fluids such as Glues, Latex or other abrasive liquids to cause seal failure allowing ingress of air reducing efficiency, and consequential loss of product.

Owing to the tough, hard wearing hose, slow speed and gentle action, pumps can handle the most abrasive of slurries from mining, biogas or dewatering and other applications which may contain sharp particles or debris.

Furthermore due to the units construction and absence of valves and seals, the pump can operate without fluid and not suffer damage making it ideal for dry, abrasive or viscous sticky liquids which would cause issues to other pump designs.

Low Shear

The nature of movement within such designs is gentle meaning they handle sensitive liquids without changing consistency or damage to a fluids cell culture.

Peristaltic Pumps can be fitted with either Internal rollers which gently compress the hose for pressures up to 8 bar, or shoes for generating high pressures up to 16 bar. When rollers are fitted units can operate at as low as 1Hz drastically reducing the agitation of any liquid, but also increasing the accuracy of dosing to within +- 1% whilst reducing energy consumption by up to 30%.

Self Priming

Due to their positive displacement design, Peristaltic Pumps are self priming up to 8M vertically with the inlet and outlet rotated to match the installation. This allows them to be installed in a variety of locations outside of the fluid and not solely at the bottom of a tank in hard to reach and access locations. Motors can be installed vertically reducing the units footprint.

Variable Flow, Reversible or Intelligently Controlled

Due to the nature of design the pumps are known as a volumetric pump meaning that flow rate is proportional to speed, but pressure remains constant. Their rotation can also be reversed meaning they can be utilized in a number of scenarios such as container filling, or emptying, but can also be utilized to ensure any associated equipment connected to the unit such as hoses can be drained if required.

With the recent release of units with touch screen display, intelligent controls, and integrated variable speed drive, units can be configured to easily batch, control flow or pressure and provide feedback if certain programmed conditions are met.

Temperature Tolerant

Peristaltic Pumps can not only handle temperatures up to 100°C, and operate within large temperature bands, where as other positive displacement pump types such as progressing cavity must be operated within narrow bands of temperatures and air operated diaphragm pumps have a limit of 80°C.

A Case in Point –24 Hour Remote Wastewater Sampling across 15 locations

A customer contacted North Ridge Pumps with a requirement to remotely sample wastewater 24 hours a day, 7 days a week at set intervals across 15 locations. They needed to sample dirty water where water levels were very low at times meaning pumps were susceptible to dry running, there were fluctuating inlet pressures and a possible ingress of solids including grass, twigs and mud ruling out many pump technologies.

They needed a low maintenance solution to pump at very low pressures, with a flow requirement up to 500Lhour. Due to the remoteness of testing locations, and sampling required at various hours throughout the day they wanted to remotely control pump speed via a single-phase supply, have the ability to reverse units should they become clogged and have a way of detecting if the hose required replacement.

Our customer initially trialed a unit to check that the system performed as required, before ordering an additional 14 3/4"Peristaltic Pumps complete with single phase inverter for speed control, hose leakage detector to enable the operator to know should the only wearing part fail via their installed PLC Controller, and with a remote input for reversing of the pump should any blockages occur. The units were supplied with forced air cooling allowing a wide operating flow with pump speed varying between 4 and 105 revolutions per minute.

As the pump supplied is of roller design they are expected to experience as much as 30% reduction in unit power consumption compared to traditional designs of peristaltic pumps, extended hose life and see many years of trouble-free service with inspection and lubrication intervals as much as 12 months apart.

If you have a dosing or metering application and are unsure of the most appropriate solution, consult with us to see how we can help.

As North Ridge Pumps are not tied to a specific pump technology we can select the most appropriate pump for your application.

Visit us at www.northridgepumps.com, contact us on live chat or speak to a Technical Sales Engineer on +44 (0) 1773 302 660.

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...