Cwmbran-based subcontractor James Brown Industries receives two-thirds of its business from companies in the oil and gas sector. Earlier this year, one customer significantly increased the volumes of stainless steel and nickel alloy components it was ordering for daily Kanban delivery in boxes containing anything from 8- to more than 600-off. In addition, new component variants were being added.

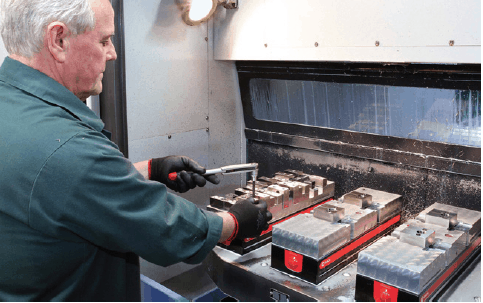

Three dedicated, twin-pallet, three-axis vertical machining centres (VMCs) on the shop floor were struggling to keep up, even working around the clock. The problem was solved by adopting new, more advanced component fixturing methods supplied by 1st Machine Tool Accessories (1st MTA).

Water Sector Talent Exodus Could Cripple The Sector

Maybe if things are essential for the running of a country and we want to pay a fair price we should be running these utilities on a not for profit...