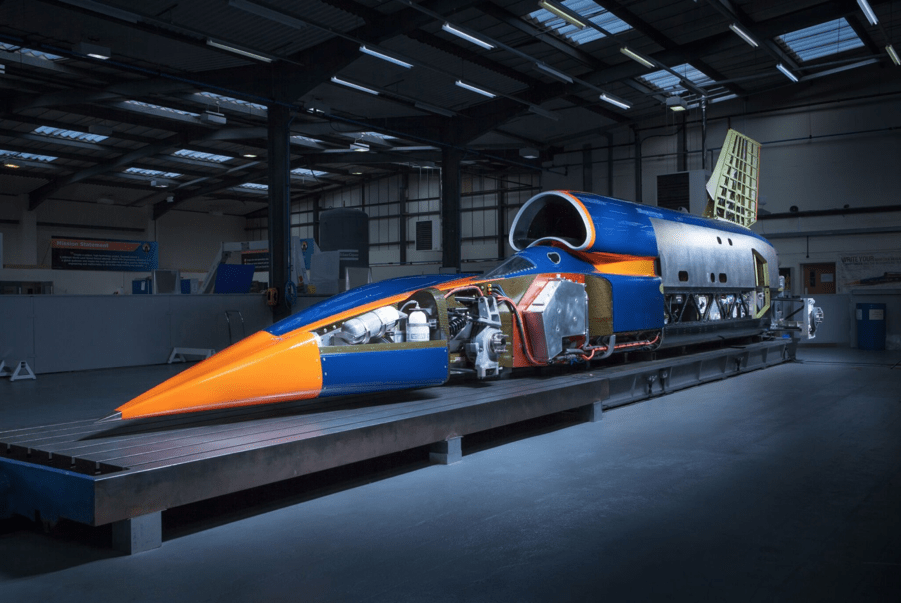

HBM is pleased to announce its involvement in the Bloodhound Project, a ground-breaking initiative that will see the development of a 1,000mph vehicle, designed to break the world land-speed record.

Powered by a Eurojet EJ200 engine, a cluster of Nammo hybrid rockets and a Jaguar V8 motor pumps oxidiser to the rocket, the body, chassis and control systems of Bloodhound meanwhile rely on a range of advanced design and manufacturing techniques, which have been provided by the Advanced Structural Testing Centre (ASTC) in Sheffield.

As part of its research towards optimising the Bloodhound supersonic car, the ASTC opted to utilise the MGCplus data acquisition system from HBM for a number of its test and measurement tasks, including load and displacement measurement, while testing rear pull-rod suspension component and front suspension roller bearings.

By strategically placing sensors at different points on the car to measure parameters, such as movement of parts, temperature and how much the suspension moved as the car was driving – all important factors when a car is travelling at over 1,000mph – signals were compared by the MGCplus data acquisition system with its stored calibrations, and a value for the properties was calculated and recorded. Following this success, ASTC also deployed the latest Quantum X system from HBM for other smaller, more flexible applications.

HBM data acquisition systems are suitable for a wide range of vehicle testing applications. With more than 1000,000 MGCplus channels in different applications worldwide, HBM’s MGCplus system has gained acceptance as a measurement standard which features a wide spectrum of supported transducers and standard PC interfaces that users demand from a leading and integrated measurement device.

National Gas receives funding to develop Gravitricity underground hydrogen storage system

One single rock salt mine - Winsford - has 23 <i>MILLION </i>cubic metres of void and even allowing for 10% of that void set aside for hazardous waste...