A comparative review of Metal Folding and Bending from Omnidex Laser.

A comparative review of Metal Folding and Bending

Introduction

In metal fabrication, metal folding; the transformation of flat material sheets into 3D structures has gained a lot of popularity in recent years. Sheet Metal Bending and metal folding have emerged as essential manufacturing techniques based on a broad range of materials and thicknesses. Bending and folding techniques accomplish material shape transformation by inducing changes in the required combination of surface topology and geometrical aspects of the material. However, these techniques are often limited by: inherent processing constraints, the type of material, the material thickness as well as the rational design or pattern of the product to be manufactured. The main purpose of this article is to compare the difference between metal folding and bending techniques based on the material type and the material thickness.

Sheet metal bending

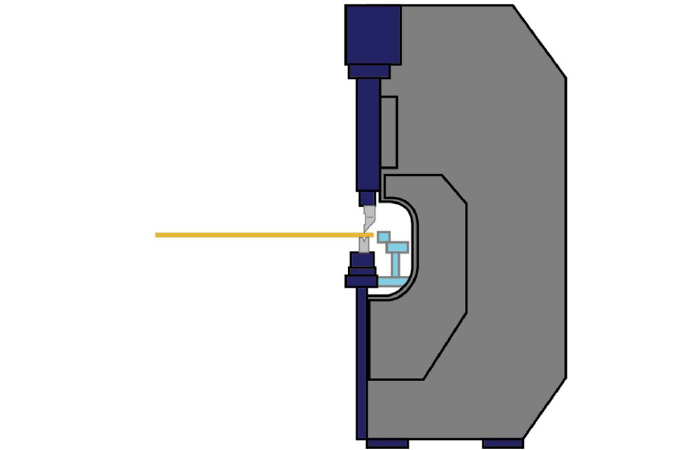

Bending technology is often associated with various processes and machines employed in sheet metal fabrication. Such machines include both press brakes and panel benders, but press brakes are the most common bending machines employed in various fabrication shops. Bending using a press brake tooling is often accomplished in various steps.

The sheet metal is first held through clamps between a die and a matching punch. The ram of the machine, fixed with a punch, moves downwards thereby forming the desired bend.

Similarly, in panel bending, the metal sheet is positioned and held below the blank holder’s tool which often descends on the metal sheet and clamps it in place. With the workpiece material protruding on one side of the machine the bending blades from above and below move to bend the material.

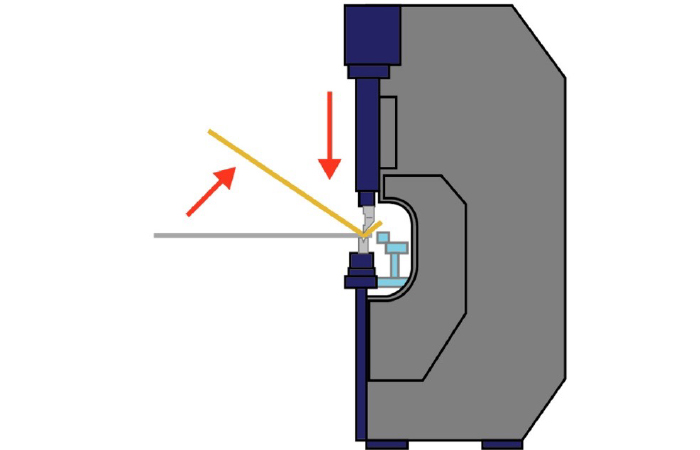

The following Figure 1, illustrates the bending mechanism.

Figure 1.1 Illustrates the bending machine holds and supports the weight of the sheet metal.

Figure 1.2 Illustrates how the bending machine bends the upper ram into the bottom die.

Omnidex Laser Scotland- Amada-HFE-M2-Machine Bending Process

Metal Folding Principles

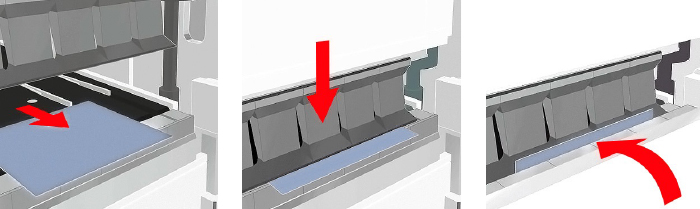

In folding, the metal sheet is typically positioned and tightly held using a clamping beam tool. During the folding cycle, the beam swings up or down around a pivot point, and the workpiece is folded into the required shape.

- The blank is placed on the CNC-controlled integrated sheet support back gauge system.

- Blank is clamped between an upper beam tool and a lower clamping beam.

- The folding beam then sweeps up or down in accordance with the programmed direction of the first flange.

- It takes only one set of universal tools to complete the job.

Figure 2: The folding mechanism

Comparative review of Metal Folding & Bending operations

Accuracy

The dimensional accuracy achieved by folding is controlled by the metal folding machine – the bending edge is utilized as a reference while the folding angle is controlled by the flange angle of the folding machine. This ensures high precision. Conversely, bending has a lower short edge dimensional accuracy owing to back gauge positioning. In this sense, errors may accumulate on the inner surface since the bending is controlled by the upper die pressing amount with respect to the thickness of the material.

Sensitive material surfaces

Bending induces surface scratches on the workpiece since the material workpiece often moves relative to the lower die of the machine. This results in the indentation on the material surface. Similarly, a large workpiece may require many turnovers during a complex folding process and this may inevitably induce scratches on the surface of the workpiece. Conversely, folding operations do not induce surface scratches as the material rests on the metal folding machine table and the process is performed at a shorter cycle time and without the need for turnovers. This results in high surface quality.

Drive

Metal folding machines often employ all-electric drive build designs which require lower maintenance and not susceptible to environmental factors. This results in high folding accuracy. On the other hand, bending machines are often hydraulically driven, hence requires high-level maintenance and also may be susceptible to environmental factors.

Material consideration in metal folding and bending

The most important material property considered during bending and folding operations is malleability. Malleability is a measure of a material’s ability to be deformed without cracking. Malleable materials are easy to bend and fold without cracking. However, less malleable materials often require heat treatment to achieve desirable bending and folding effects. Table 1 illustrates the materials considered for bending and folding.

Table 1: Material considered for bending and folding

| Material type | Malleability |

| Aluminium 6061 | · Has very low malleability hence difficult to bend as it results in cracking |

| Aluminium 5052 | · Highly malleable and therefore easily folded and bent as desired |

| Annealed steel | · Bendability and foldability depend on the alloy designation. 4140 steel exhibits good malleability |

| Brass | · A high content of zinc reduces malleability. However small bending for a complex part may require heat treatment |

| Copper | · Very malleable hence easy to fold and bend |

| Mild steel | · Has high malleability |

| Stainless steel | · Grade 430 and 304 stainless steel have good malleability |

Material thickness

Generally, folding operations can be performed on relatively thicker material as compared to bending. However, the thickness of a material that can be achieved through folding and bending operations depends on the type of material. Table 2 illustrates the maximum thickness that can be achieved in folding and bending operations.

Table 2: Maximum thickness for folding and bending processes

| Process | Material | Thickness | Max. Fold / | Max. fold / bend Angle |

| Metal Folding | Mild steel | 15mm | 8m | 45 degrees |

| Aluminium | 15mm | 8m | 45 degrees |

| Stainless steel | 10mm | 8m | 45 degrees |

| Metal Bending | Mild steel | 6mm | 4m | 90 degrees |

| Aluminum | 8mm | 5m | 90 degrees |

| Stainless steel | 4mm | 2m | 90 degrees |

Material thickness tolerances

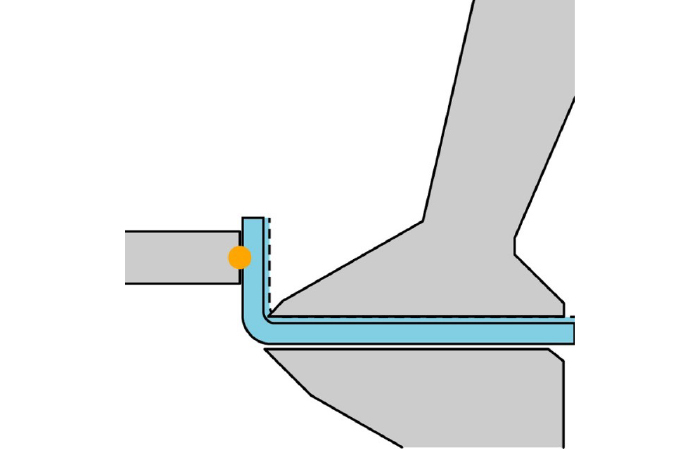

In the metal folding sequence, the tool for the folding beam approaches the contact from the outside of the workpiece and the material often moves at an exact position as per the programmed angle. As such, the reference side of the material is only on the outer surface of the material hence ensuring high precision. The movement of the metal folding machine as per the programmed folding angle ensures extremely high accuracy. The tolerances of the material thickness do not affect the respective bending angle hence no angle measuring instrument is required.

Figure 3: Material thickness tolerance during folding

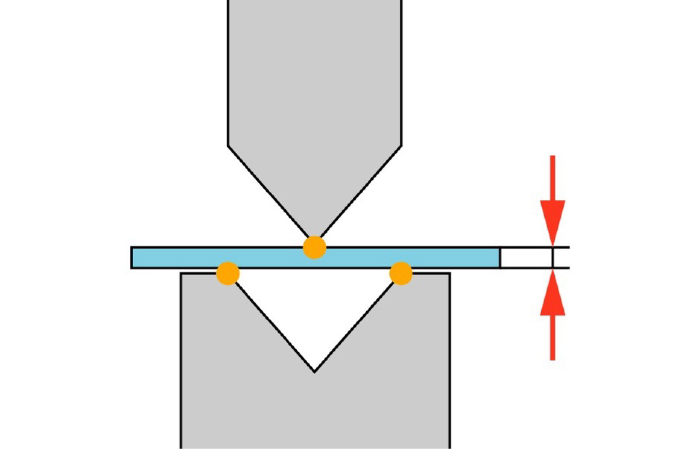

On the other hand, in metal bending sequence, the machine’s punch often contacts the material from both sides of the die. This implies that contact points are on both material sides which may compromise the dimensional integrity. The bending angle is measured from the linear upper movement of the tool. The tolerances for the sheet thickness may result in variation in the bending angle hence, during bending, an inflexible measuring instrument is required for compensating the variances.

Figure 4: Material thickness tolerance in bending | Omnidex Laser Scotland UK

Conclusion

The article provided a comprehensive review of the bending and folding processes that are employed in material fabrication.

A review of the operational techniques shows that Folding Machines are well suited to handling large panels, multiple-setup components and surface-sensitive materials. When the overall weight of the part is taken into consideration, it becomes easier to maneuver and position large panels when a sheet support system and back gauge system are used. Thus, the cost of production can be minimized.

It has also been determined that folding offers outstanding advantages over bending. Due to its machine-controlled folding angle, folding provides high precision and accuracy; thereby, performing well with thicker materials than bending. Compared to the bending operation, folding produces high-quality products that are free of surface scratches.

Omnidex Laser offers a variety of sheet metal folding services. We are equipped with the Amada HFE-M2 2204 press brake metal folding machine to meet and satisfy the needs of various industries.

Omnidex Laser is always excited to work with our customers and to meet each of their project’s requirements and specifications.Contact Us

Hard hat mounted air curtain adds layer of protection

Something similar was used by miners decades ago!